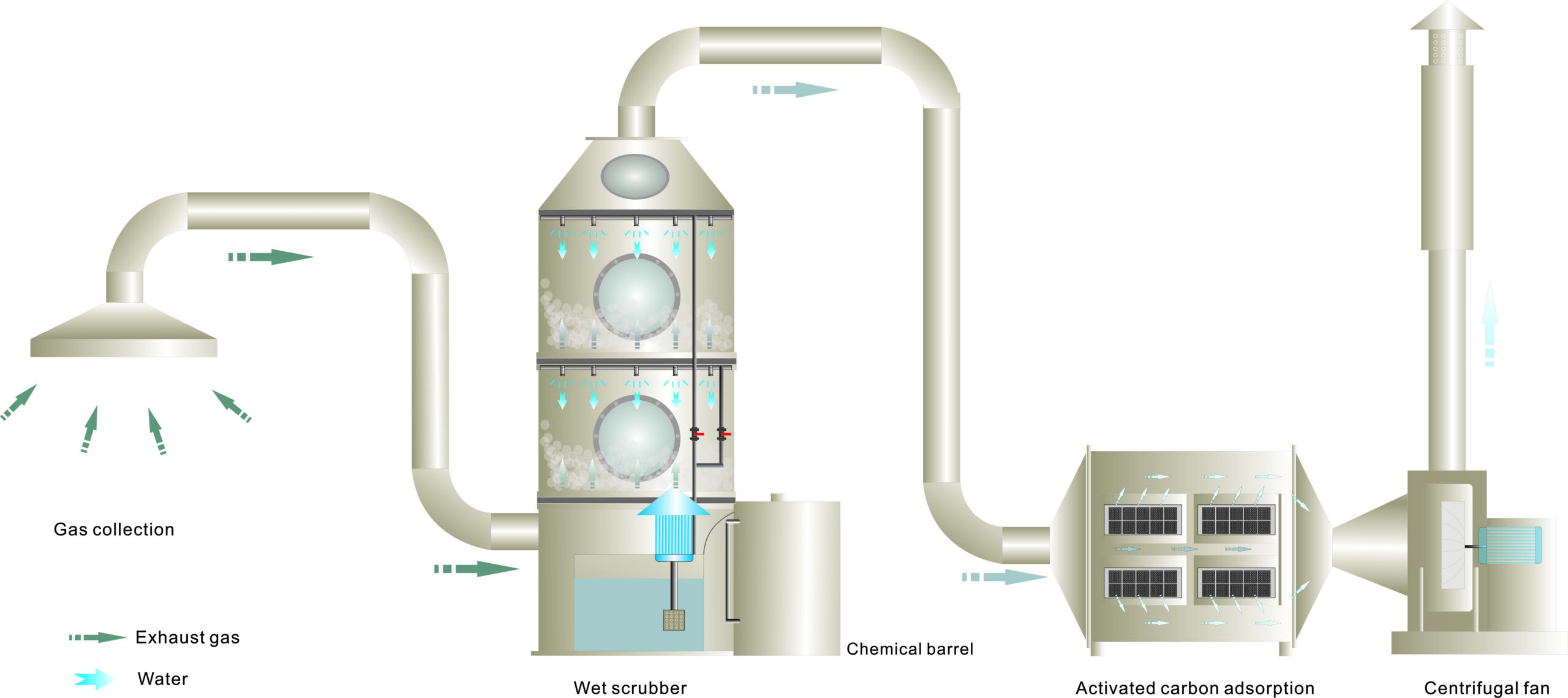

Description

product descriptionPP material water scrubber: built-in high-pressure spray device, integrated grid plate, multi-sided ball packing. It can efficiently filter 95% of dust particles in the exhaust gas.

1. Equipment introduction:

The Water Scrubber is again called a washing tower. It can be used to treat industrial flue gas and dust and absorb particulate dust in exhaust gas through a high-pressure spray. Mainly used in food processing plants, metal smelting plants, fertilizer production workshops, etc.

PP material water scrubber structure and function

2. Structure and working principle

Structure

The structure of the PP material water scrubber: Different from the structure of other wet dust collectors, the water scrubber is equipped with a multi-layer high-pressure water spray device and 3 layers of multi-faceted spherical packing.

Features

Dust gas enters the tower body from the bottom of the scrubber and is sent into the intake space by a high-pressure centrifugal fan. The dust particles will pass through 3 layers of multi-faceted spherical packing layers and 3 layers of high-pressure water spray devices. The dust particles in the exhaust gas will be completely absorbed by the high-pressure water mist. , The dust will be collected in the water storage tank at the bottom of the scrubber, and the purified waste gas will be sent to the activated carbon tank.

3. Features of this equipment:

1. The size and function of the equipment can be customized freely.

2. PP plastic production, low manufacturing cost, and transportation cost.

3. Polypropylene material has the characteristics of flame retardant, anti-chemical corrosion, high hardness, etc.

Technical Parameter Table :

1. This form is a common size and we can customize different sizes and requirements according to your needs.

2. The material is polypropylene.

3. Equipment design wind speed 1.8m/s