Description

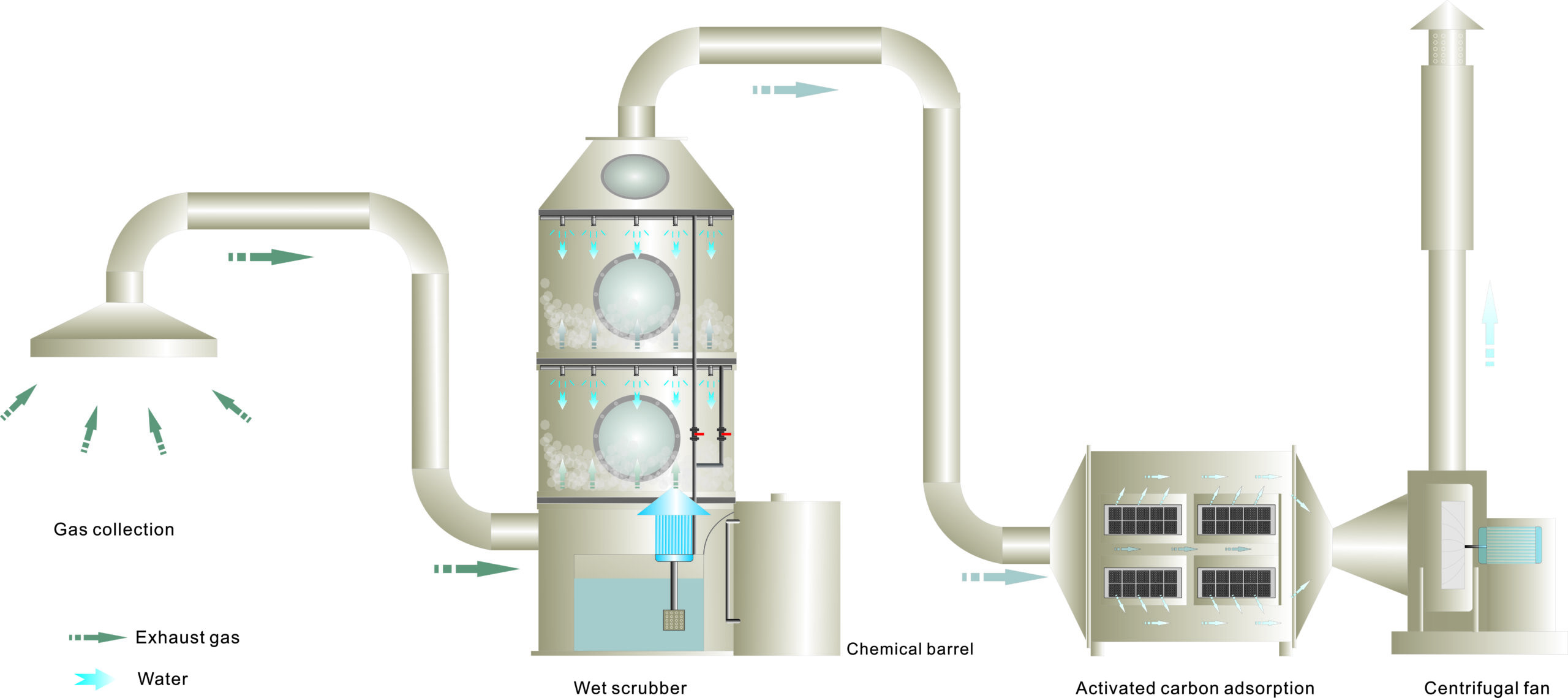

As a spray absorption equipment has been used in exhaust gas purification. It develops the concept of vulcanized bed into the vapor transfer equipment, which makes the filler in the spray tower in a fluidized state, thus making the mass transfer process can be strengthened. His characteristics are high airspeed, processing capacity, the lightweight of the tower, relatively uniform distribution of vapor, not easily blocked by solid and viscous materials. Especially because of the strong turbulence in the tower, the mass and energy transfer can be strengthened, so it can reduce the diameter of the tower and reduce the height of the tower. The tower handles a large amount of air, the airspeed of 1.5 to 6.0m/s, spray density 20 to 110m3/(m2.h), the pressure loss of 1500 to 3800Pa, The defog removal device of the washing tower adopts the spinner defog device, which uses the action of centrifugal force to remove the mist by making the gas produce rotating motion through the tower plate, and its defog efficiency can reach 98%-99%, and the structure is simple to pressure drop is small.

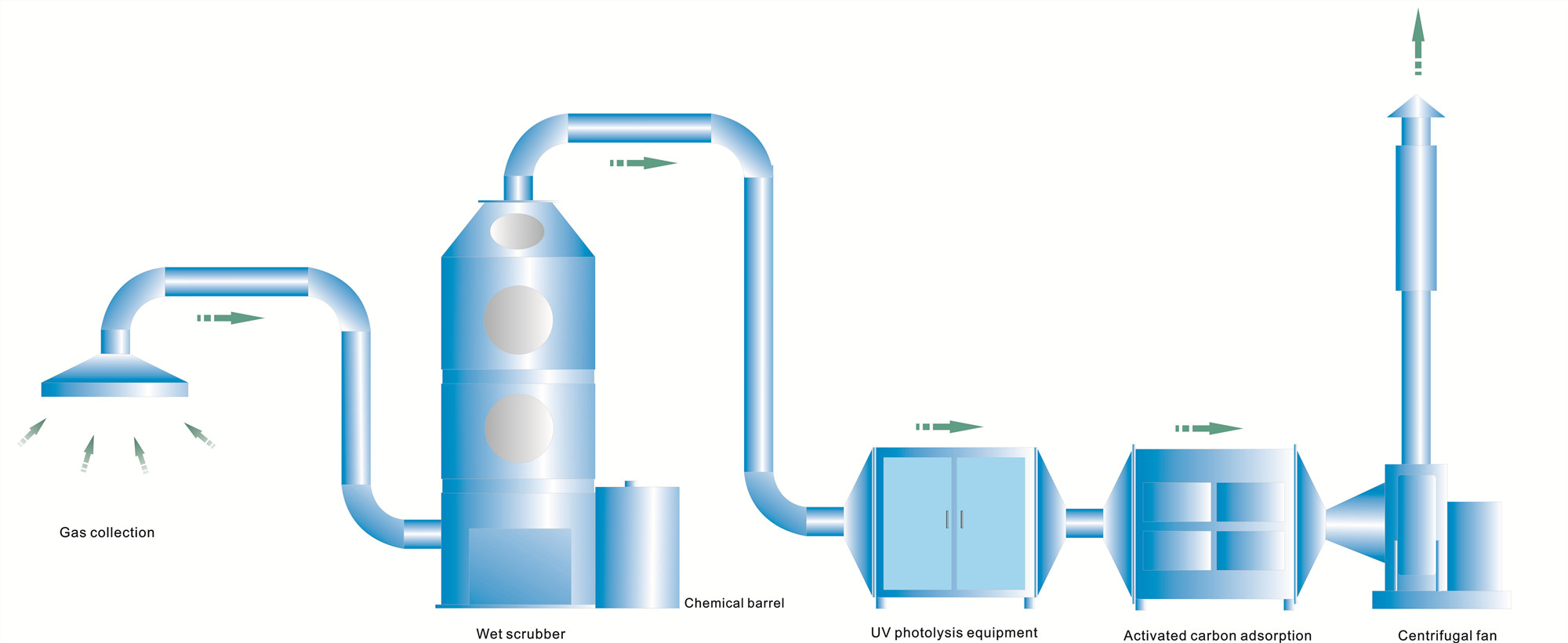

Industrial waste gas treatment system design process

1. Waste gas collection

The first is to collect exhaust gas. In the workshop where the exhaust gas is generated, a hood is installed directly above it. It is usually made of polypropylene (PP) anticorrosive material. Because it is used to collect exhaust gas, it is called an air collecting hood. However, in some workshops, waste gas is generated at many points and cannot be collected effectively. In this case, the gas in the entire workshop can be pumped away for processing.

2. Selection of waste gas treatment equipment

After the waste gas is collected, it passes through the polypropylene pipeline and passes through the wet gas scrubber of the industrial air pollution control system. The gas filtered by the scrubber can meet the emission standard. For different waste gas, the effect to be achieved is different, and the selected equipment is also different. Industrial waste gas treatment mostly adopts a spray packing tower for pretreatment. The temperature is a bit high. After the spray packing tower is pre-treated, the purification efficiency of subsequent equipment can be better improved. Of course, if there is more dust, you must use a cartridge dust collector or a bag dust collector to remove the dust. The spray packing tower is only suitable for a small amount of dust.

Rear centrifugal fan. The function of the glass fiber reinforced plastic centrifugal fan is to provide power for the scrubber system so that the exhaust gas is discharged through the exhaust cylinder after being processed by the purification equipment.

3. Determination of exhaust gas treatment air volume

The exhaust gas treatment air volume is determined, such as the air collecting hood, calculated at 2000 air volume per square meter. If it is fugitive emissions, exhaust gas cannot be collected. Only the gas from the entire workshop can be extracted so that the entire workshop can be calculated. According to the exhaust gas concentration and treatment effect, choose different air exchange times. Some choose 6-8 times, some choose 20-30 times, and some choose 100-150 times. For example, the workshop volume is 1000 cubic meters. Note that it is a cube instead of a square, that is, the length * width * height of the workshop, and the number of air changes is 8 times, so the processing capacity per hour is 8000 air volume.