Description

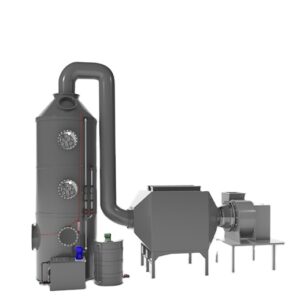

product descriptionHigh-efficiency gas purification tower: The contact between gas and liquid is used to transfer the pollutants in the gas to the liquid, and then the clean gas is separated from the contaminated liquid to achieve the purpose of purifying the air.

Equipment introduction:

The waste gas passes through the high-efficiency spray tower and is treated by gas-liquid reverse absorption, that is, the liquid is sprayed down in the form of mist (or small droplets) from the top of the tower. The exhaust gas flows from the tower body (countercurrent flow) to achieve the purpose of gas-liquid contact. This treatment can cool the exhaust gas, condition the gas and remove particles, and then pass through the mist removal section before being discharged into the atmosphere.

Structure and working principle

structure

The structure of the PP gas scrubber is:

1. Washing tower spray system

2. Filling layer filler

3. Medicine storage tank

4. Inspection window and maintenance access hole

5. Water level control device of circulating water tank

6. Pressure gauge

principle

The high-efficiency spray tower system and fan unit suck the collected waste gas into the acid mist scrubber, and flow through the filling layer (gas/liquid contact reaction medium), so that the waste gas is in full contact with the liquid medicine (washing liquid) flowing on the surface of the filling, In order to absorb the acidic or alkaline dirt contained in the exhaust gas. After washing, the waste liquid is collected in the sump and then discharged to the wastewater system for treatment.

Features of this equipment:

1. The water-washing waste gas treatment system is cheap and the treatment method is simple.

2. The vertical structure is most suitable for installation in economical space.

3. It can be used for the treatment of various harmful gases such as H2S, SOX, NOX, HCI, NH3, CI2, and other gases.

Technical Parameter Table :

1. This form is a common size and we can customize different sizes and requirements according to your needs.

2. The material is polypropylene.

3. Equipment design wind speed 1.8m/s