Industry Introduction

Spraying refers to covering the surface of the metal and non-metal with a protective layer or a decorative layer and is the basic technical means used for product surface protection and decoration. The coating process can be simply summarized as pre-treatment → spraying → drying or curing. Pre-treatment generally includes degreasing, rust removal, and passivation (phosphating) processes. According to different coatings and anti-corrosion requirements, treatment methods such as oil removal, rust removal, and phosphating should be selected according to the condition of the raw material of the workpiece. In the pre-treatment and rust removal process, sandblasting shot blasting, or polishing processes are also used in different departments of different industries as needed.

Industry characteristics

According to the paint spraying production process, paint spraying waste gas mainly comes from the pre-treatment, spraying, and drying processes. The pollutants emitted are mainly: dust or paint mist generated during the pre-treatment process, paint mist, and organic solvents generated during painting. Organic solvents are generated during drying and volatilization. The paint mist mainly comes from the scattered parts of the solvent-based paint in the air spraying operation, and its composition is consistent with the paint used. Organic solvents mainly come from solvents and thinners in the coating process, and most of them are volatile emissions. The main pollutants are xylene, benzene, toluene, and VOCs. The harmful exhaust gas emitted from painting is mainly concentrated in the spray paint production line, among which the spray booth, drying room, and drying room are the main sources of exhaust gas.

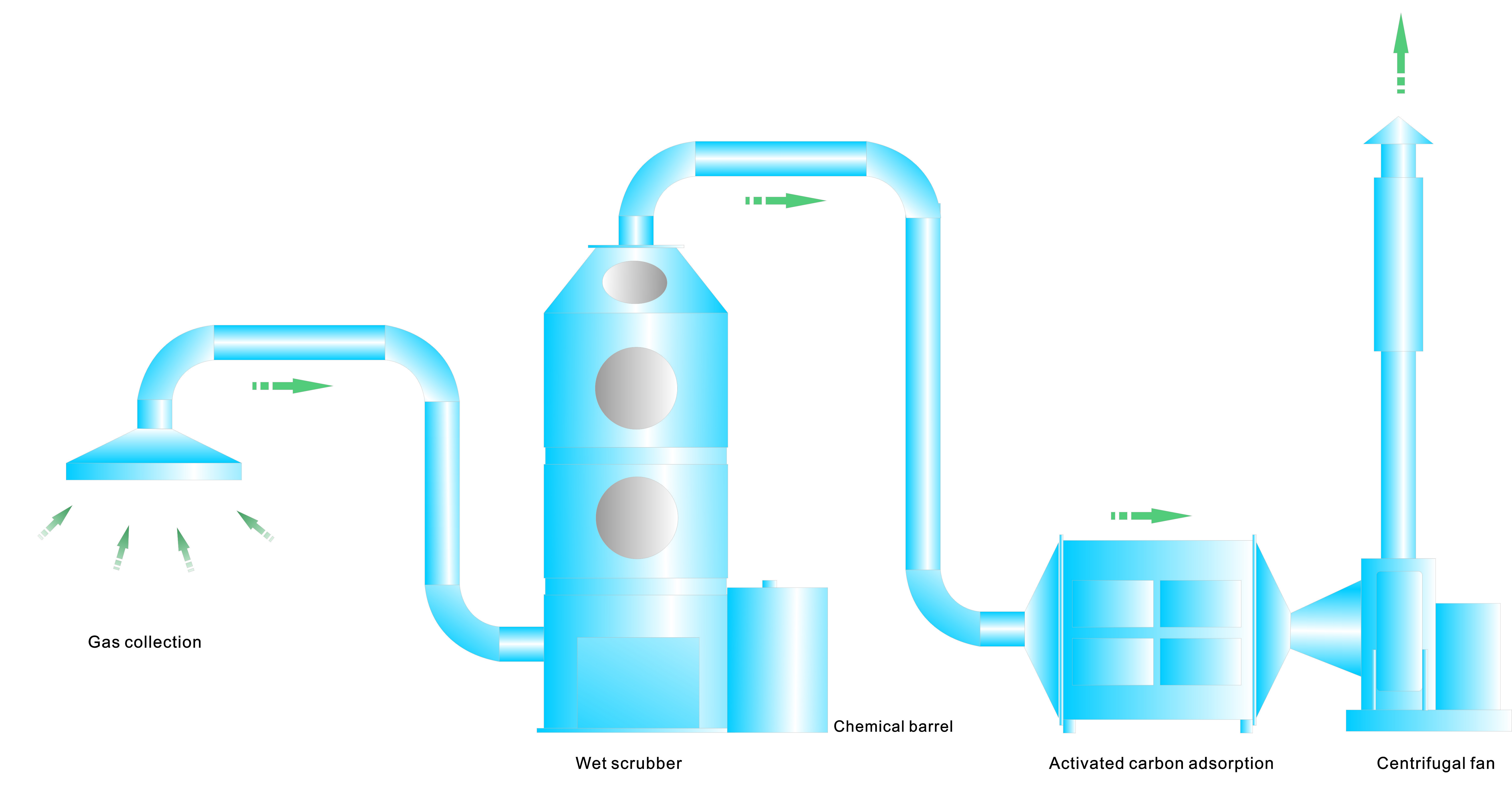

Wet scrubber + filter + activated carbon adsorption concentration+centrifugal fan

Brief description of the recommended treatment process:

For the coating industry, there are two main processes that generate exhaust gas: spraying and drying. According to the characteristics of waste gas generated in the coating industry, coating waste gas with large air volume, low concentration, and complex composition has no recycling value.

Waste gas treatment process:

Activated carbon adsorption concentration + online catalytic combustion system is purification equipment vigorously advocated by the environmental protection industry in recent years, focusing on energy saving and environmental protection concepts. Its working principle is: At present, all industries produce high-volume, low-concentration organic waste gas, activated carbon adsorption concentration catalytic combustion, mainly for the large air volume before treatment, low-concentration organic waste gas is concentrated into small air volume, high concentration After the organic waste gas is purified, the high-concentration organic waste gas adsorbed on the surface of the activated carbon is desorbed by hot air at 80°C, and the desorbed high-concentration organic waste gas is sent to the catalytic combustion oxidation furnace for 285°C-400°C During the high-temperature oxidation, carbon dioxide, and water meet the emission standards.