The volute and impeller of the PP centrifugal fan are made of PP plastic, which has the characteristics of high strength, lightweight, corrosion resistance, stable operation, and low noise. It can be used to transport corrosive gases, such as hydrochloric acid mist, sulfuric acid mist, and nitric acid. Fog and so on. Gas temperature≤60℃, relative hard particles≤100mg/m3. PP fans are not allowed to treat corrosive gases containing aromatic compounds, halogen derivatives of aliphatic and aromatic hydrocarbons, ketones, and other corrosive gases.

The working principle of the PP centrifugal fan is that when the motor rotates to drive the fan impeller to rotate, the gas between the impeller blades also rotates, and the gas is thrown out under the action of centrifugal force. The gas flow rate increases, so that the kinetic energy of the gas is converted into static pressure energy, then as the fluid is pressurized, the static pressure energy is converted into velocity energy, and the gas is discharged through the exhaust port, and a certain negative pressure is formed in the middle of the impeller. Fill in immediately under the action of atmospheric pressure, and continuously discharge and fill in gas under the continuous rotation of the PP fan impeller, so as to achieve the purpose of continuous air blowing. Under the same power, the wind pressure and air volume of the PP fan are generally inversely proportional. Under the same power, the wind pressure is high, the air volume will be relatively low, and the wind pressure is high, the wind pressure will be reduced so that the power efficiency of the motor can be fully utilized.

PP fan is ideal corrosion-resistant ventilation equipment in industrial production at present, with high strength, strong corrosion resistance, stable operation, and low noise. The technicians of Xicheng Environmental Protection Equipment Company have carefully designed and improved PP fans for many years, and their performance and quality have been improved day by day. They have widely replaced fans of other materials.

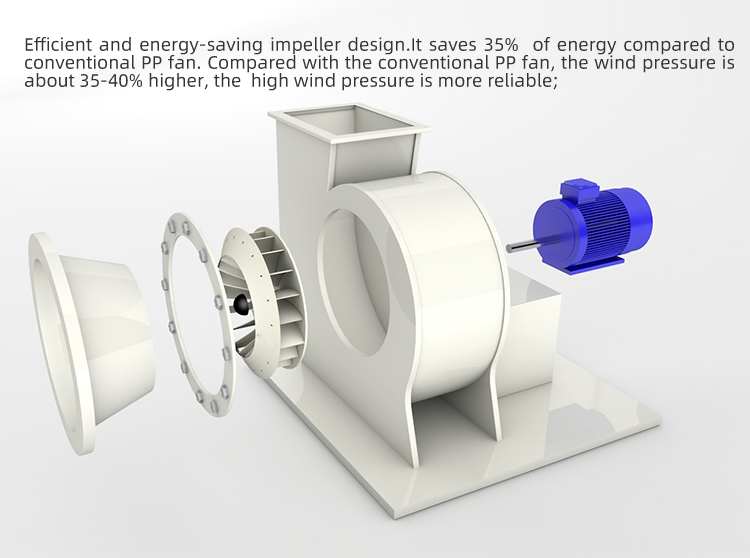

The PP fan adopts the A-type structure, that is, the motor is directly connected to the impeller, that is to say, how many revolutions are selected for the motor speed, the impeller of the PP fan is how many revolutions and the PP anti-corrosion fan is usually equipped with two types of motors, which are 1440 revolutions. /Min and 2900 revolutions/min, the motor power is available from 0.75KW to 11KW. The structure of the PP fan is mainly composed of impeller, volute, motor, shock-absorbing base, and so on. The base frame is made of profiled material and fixedly connected to the volute of the PP fan.

The volute of PP centrifugal fan refers to the parameters of metal fan F4-72. The impeller is made of modified reinforced PP polypropylene injection molding. PP fans are widely used in scientific research, chemical industry, metallurgy, electronics, medicine, textiles, instrumentation, electroplating, mining, schools It is used for ventilation in hotels, guesthouses, laboratories, environmental protection equipment, and other industries to remove acid and alkali harmful gases.