The centrifugal blower, also known as a centrifugal fan, is a mechanical device used to move air or other gases in various industrial and commercial applications. It operates based on the principle of centrifugal force, hence the name.

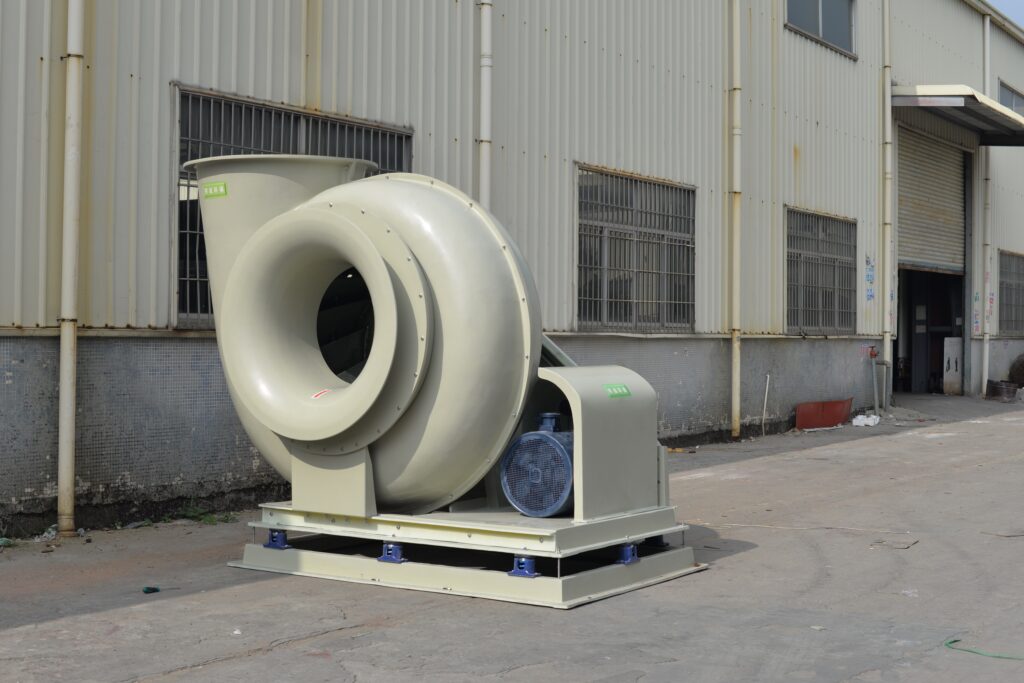

Centrifugal blowers consist of several key components, including an impeller, a casing, and a motor. The impeller, which is a rotating wheel with blades or vanes, draws in air or gas and then accelerates it outward using centrifugal force. The casing, typically in a scroll or volute shape, helps convert the high-velocity air or gas into increased pressure. The motor provides the rotational power to drive the impeller.

When the impeller rotates, the blades or vanes push the air or gas radially outward, creating a centrifugal effect. This centrifugal force increases the pressure of the air or gas, allowing it to be moved through ducts, pipes, or other systems.

Ventilation: Centrifugal fans are commonly used in HVAC systems to provide fresh air circulation and remove stale air from buildings. They help maintain indoor air quality and create a comfortable environment by exchanging and distributing air.

Industrial Processes: Centrifugal fans are vital in industrial processes where the movement of air or gas is necessary. They are used for applications such as exhaust systems, fume extraction, air scrubbing, dust collection, and cooling of equipment or processes.

Air Handling Units: Centrifugal fans are often found in air handling units (AHUs), which are components of HVAC systems that condition and distribute air within buildings. They help deliver the required airflow and pressure to ensure proper ventilation and temperature control.

Drying and Cooling: Centrifugal fans are employed in processes that involve drying or cooling operations. They help remove moisture or excess heat from materials, such as in drying ovens, cooling towers, or heat exchangers.

Pneumatic Conveying: Centrifugal fans are used in pneumatic conveying systems, where they facilitate the movement of bulk materials through pipelines by creating the necessary air pressure or vacuum.

Power Generation: Centrifugal fans are utilized in power plants, including thermal power plants and industrial boilers, to supply air for combustion and to remove exhaust gases.

Wastewater Treatment: Centrifugal fans play a critical role in wastewater treatment plants by providing aeration for biological processes, promoting the growth of beneficial microorganisms that aid in treating wastewater.

Chemical and Process Industries: Centrifugal fans are widely used in chemical plants, refineries, and other process industries to handle corrosive or hazardous gases, assist in chemical reactions, and maintain process conditions.

Axial blowers and centrifugal blowers are two distinct types of fans used for moving air or gases in different applications. Understanding their characteristics and differences is important for selecting the appropriate fan for a specific use. Here’s an overview of axial blowers and centrifugal blowers:

Axial Blowers:

Airflow Direction: Axial blowers move air or gas in a straight, linear path parallel to the axis of the fan’s shaft. The airflow is primarily in the axial direction.

Design: Axial blowers consist of a propeller-like impeller with blades that rotate around a central shaft. The blades draw air in axially and propel it forward.

Pressure Generation: Axial blowers generate relatively lower pressures compared to centrifugal blowers. They are more suitable for applications that require high airflow volume but not necessarily high pressure.

Efficiency: Axial blowers are generally more efficient in terms of energy consumption since they primarily focus on moving air directly in the axial direction.

Applications: They are commonly used for applications that require large airflow volumes with minimal pressure requirements, such as cooling equipment or processes, ventilation in confined spaces, or air circulation in HVAC systems.

Centrifugal Blowers:

Airflow Direction: Centrifugal blowers move air or gas in a radial direction, perpendicular to the axis of the fan’s shaft.

Design: Centrifugal blowers typically feature a circular or scroll-shaped casing and a rotating impeller with blades or vanes. The impeller accelerates the air or gas radially outward, creating a centrifugal effect.

Pressure Generation: Centrifugal blowers are capable of generating higher pressures compared to axial blowers. They are suitable for applications that require increased air or gas pressure.

Efficiency: While centrifugal blowers may be slightly less efficient than axial blowers, they excel in generating higher pressure and handling ducted systems or complex airflow paths.

Applications: Centrifugal blowers find applications in a wide range of industries, including HVAC systems, industrial processes, pneumatic conveying systems, wastewater treatment plants, and power plants. They are preferred for applications that require both airflow volume and increased pressure.

Centrifugal blowers, also known as centrifugal fans, offer several advantages in various applications where the movement of air or gases is required. Here are some key advantages of centrifugal blowers:

Conclusion:

These advantages make centrifugal blowers a popular choice for industries requiring efficient and reliable air or gas movement. However, it’s essential to select the appropriate blower type based on specific application needs to ensure optimal performance and longevity.