PP polypropylene sheets are a new type of plastic board, and flame retardant is added to the production of ordinary PP board. The main feature is that the flame retardant PP board that burns at high temperatures will immediately extinguish the flame after leaving the fire source, preventing the spread of the flame and the occurrence of fire. Compared with PVC sheet, polypropylene sheet is lighter, easy to process, easy to weld, and does not produce harmful gases when burned.

In general, the welding method of polypropylene sheets is considered irreversible. A few processes, such as induction welding, can produce reversible components. As for which method should be selected at the beginning of workpiece design, this is important because welding methods need to describe the workpiece, and different welding methods are different.

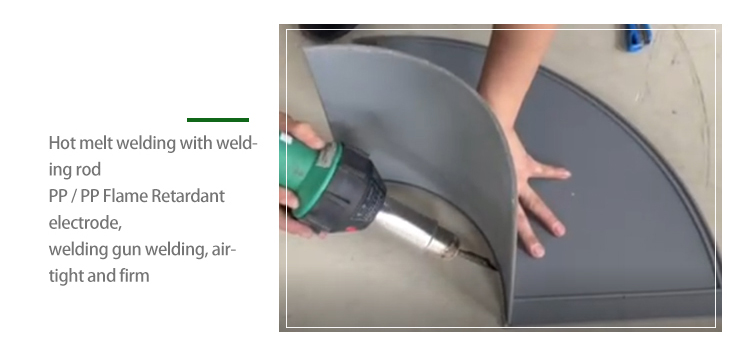

Hot gas welding is generally used for welding plastic tubes, sheets, or semi-finished products, not injection molded parts. However, many thermoplastic molded parts, especially thermoplastic automotive discs, are repaired by hot gas welding techniques. In addition, hot gas welding is sometimes used to make plastic-like molded parts.

1. Hot plate welding

is a thermoplastic welding process in which the surfaces of joined plastic parts are softened by electrically heating a metal mold. It is suitable for almost all thermoplastic products, large and small. Suitable for welding soft semi-crystalline thermoplastics such as polyethylene or polypropylene sheets. Because different mold surface temperatures apply to two other thermoplastic materials, this process is suitable for different welding materials. Hot plate welding enables high weld strength. However, the cycle time for this process can be relatively long, taking 15s for small parts and several minutes for large parts.

2. Hot gas welding

Hot gas welding is a welding method widely used to join thermoplastic profiles and sheets to produce large parts. It is suitable for repairing small injection molded and thermoplastic parts that require assembly and fabrication of prototypes. It is important to produce electrodes of the same polymer brand as the parts to be welded.

3. Extrusion welding

Extrusion welding is a welding method developed from hot gas welding.

4. Bonding

Adhesives can be used to join plastic parts made of polymers of the same material, often for edge parts made of different materials. Join thermoset plastic parts to each other, or join plastic parts to metal.

Advantages of adhesives include:

Beautiful, vivid description; uniform stress distribution; can join dissimilar materials; can provide a tight seal for air, water and gas; soft glue can absorb vibration; can be used on thin and soft substrates; supply electrical and hot edges.

Various limitations of adhesives: Uncertainty of function; Summarizing chemical process; Need for a clean surface.

Adhesive selection

The choice of adhesive for a specific application depends on the following factors: application environment, substrate surface chemistry, substrate rigidity characteristics, substrate thermal expansion coefficient, joint filling needs, and application method.

5. Solvent bonding

Solvent bonding is a method of assembling some thermoplastic parts, often used for amorphous thermoplastic parts. Solvent bonding is a simple and relatively inexpensive method for sealing and assembling stable amorphous thermoplastic parts. The low viscosity of the solvent requires that the parts to be bonded should be straight and formed to relatively tight tolerances.

Polypropylene PP sheet has low density, easy welding and processing, superior chemical resistance, heat resistance and impact resistance, environmental protection, and odorless. It is currently one of the most environmentally friendly engineering plastics. The main colors are white, and microcomputer colors, other colors can also be customized according to customer requirements.

PP polypropylene sheets are widely used in the UV and silk screen printing industry, stationery and gift industry, medicine and health industry, packaging industry, food industry, lighting industry, electronics industry, manufacturing of environmental protection equipment, industrial exhaust ducts, laboratory ventilation equipment, etc.