A wet scrubber system is critical to controlling and reducing the emissions of harmful pollutants produced by industrial processes. These systems are designed to capture, treat, and neutralize toxic gases, particulate matter, and other contaminants before releasing them into the atmosphere. The wet scrubber system is one of the waste gas treatment systems.

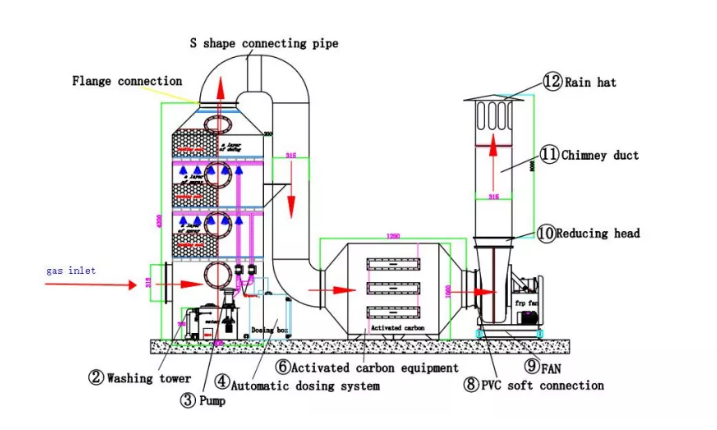

The waste gas that needs to be treated enters from the air inlet of the scrubber and flows from bottom to top inside the scrubber. The water pump pumps the chemicals in the water tank to the inside of the scrubber and sprays them from top to bottom through the nozzle. Both of them are inside the scrubber. Contact and acid-base neutralization reaction occurs;

The structure of the wet scrubber is two layers of spraying and one layer of defogging. The spraying layer is equipped with Raschig ring packing to increase the contact area and reaction time between the two so that they can fully react. The defogging layer is fitted with PP polyhedral balls. The filling is used to filter the moisture in the gas, allowing the drier gas to enter the activated carbon adsorption box for the next step of purification, while the moisture adsorbed by the polyhedral balls will condense into water droplets and flow into the bottom of the scrubber;

The activated carbon adsorption box will further absorb impurities, odors, colors, etc. in the exhaust gas, and it is very effective in treating VOC exhaust gas;

The clean gas will eventually be discharged into the atmosphere through the fan and chimney pipe;

The system is also equipped with an automatic dosing system and control electrical box:

The automatic dosing system: through the PH electrode, the PH value of the liquid can be detected, thereby feeding the information back to the electric control box. The electric control box sends instructions to the metering pump to automatically add the agent to the scrubber water tank, without the need for artificial real-time monitoring of the use of the agent.

The electric control box: controls the start and stop of the fan, water pump, and automatic dosing system.

Pollutant Removal:

High Efficiency:

Versatility:

Cooling Effect:

Gas Absorption:

Wet scrubbers are used in various industries, for example:

Wet scrubbers are an essential part of industrial air pollution control, offering high efficiency and versatility in removing a wide range of pollutants. They are particularly useful in applications requiring simultaneous removal of gaseous and particulate contaminants and where gas cooling is beneficial. However, considerations around water use, corrosion, and wastewater management must be addressed to ensure optimal performance and environmental compliance.

XICHENG EP(CN) LTD, is one of the largest polypropylene product manufacturers in China, we mainly produce exhaust gas scrubbers, activated carbon towers, ventilation pipes, and a series of plastic injection molded parts and processing parts, like ventilation accessories, plastic sheet, and tank, etc. We want to supply high-class products and satisfy every customer’s needs.

Contact: Lora Wu

Tel/WhatsApp: +86 13378669672

Email: lora@china-xicheng.com