What are the types of air pollution control systems and equipment? Air pollutants almost pervade all aspects of the entire industrial process, including raw material procurement, product manufacturing, maintenance, and hazardous chemicals disposal. Therefore, there are many different types of air pollution control systems and equipment that can be used for air pollutants generated from mobile and stationary sources in various industries. Manufacturers of industrial scrubbers take you to understand the control equipment of air pollutants, such as pollutants produced in the combustion process.

In the industrial environment, air pollution control systems and equipment is a collective term that refers to equipment and systems used to regulate and eliminate the emission of potentially harmful substances (including particulate matter and gas) discharged into the air by manufacturing, process systems, and research applications. Atmosphere And the surrounding environment. Control equipment is used in many industries to prevent the release of chemicals, vapors, and dust, and to filter and purify the air in the working environment. Generally, fans or blowers discharge industrial waste gas and waste gas directly into air pollution control systems and equipment and systems, which use one or more of the following processes to remove or reduce air pollutants.

Combustion (that is, to eliminate pollutants)

Conversion (ie, chemical conversion of pollutants into less harmful compounds)

Collection (ie, removal of pollutants from exhaust gas before it is discharged to the environment and atmosphere)

Certain types of air pollution control systems and equipment that are used in industrial applications and utilize one or more of the aforementioned methods for removing or reducing air pollutants include:

Scrubbing towers are some of the most commonly used air pollution control systems and equipment in manufacturing and processing facilities. Industrial air scrubbing towers use physical processes (ie scrubbing) to remove particulates and gases from industrial emissions, such as chimney exhaust (for exhaust gas scrubbers). In terms of) before being released into the atmosphere. There are two main types of scrubbers: dry scrubbers and wet scrubbers.

Dry scrubber

Dry scrubber, also known as dry adsorption scrubber, injects dry neutralizing chemical reagents (such as sodium bicarbonate) into the discharge stream to cause the gaseous pollutants contained in it to undergo a chemical reaction, which can neutralize pollution Or convert it into harmless substances. Once the chemical reaction is over, the filter in the washing chamber collects and removes waste reagents from the clean exhaust gas. In some cases, the collected reagents can be cleaned and reused in future dry washing processes, but if this is not possible, the washing waste must be disposed of by professionals. Generally, dry scrubbers are used to remove or offset acid gases in industrial waste gas.

Wet scrubber

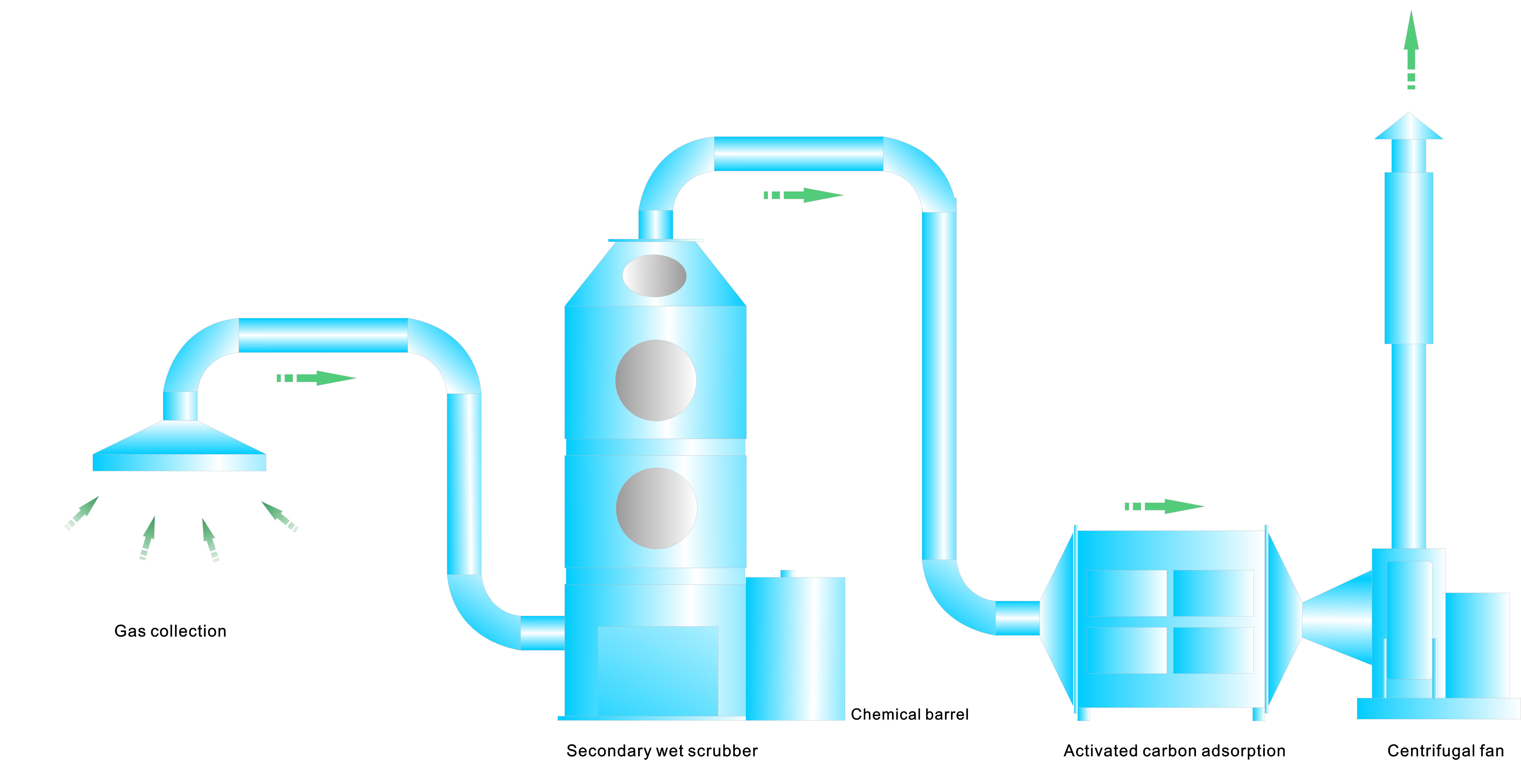

Wet scrubbers, also known as wet adsorption scrubbers or wet collectors, use liquid solutions (usually water) to collect and remove water-soluble gases and particulate pollutants in industrial waste gas. The wet scrubbing process either passes the air stream through the liquid solution or injects the liquid solution into the air stream. When the gas stream comes into contact with the liquid, the solution absorbs contaminants and removes them from the gas stream. The types of wet scrubbers available include PP pipes, packed beds (industrial air scrubbers), and packed bed wet scrubbers.

Washing tower

Air filter

An air filter is a device used to control air pollution. It uses a specific type of filter media (for example, fabric, sintered metal, ceramics, etc.) to collect and remove dry particles and pollutants, such as dust, pollen, microorganisms, and chemicals Wait. Flowing through the air. These devices are used in residential, commercial, and industrial applications to remove pollutants in the exhaust gas and improve air quality in the work environment. For industrial applications, there are several types of air filters available, including HEPA filters, fabric filters, and cartridge dust collectors.

The industrial HEPA filter is a type of air filter that uses glass fiber filter mats to mechanically remove suspended particles in the air from the working environment, such as pollen, smoke, dust, and biological pollutants. Generally, the fiber size of the glass fiber filter mat is between 0.5 and 2 μm. When the blower component of the filtration system passes air through the HEPA filter, particles can stick or become embedded in the fibers. In addition, particles passing through the filter collide with the gas contained therein, which slows down their speed and increases their chances of sticking or embedding in the filter.

Fabric filter

Fabric filters (also called dust chambers) are a type of air filter that usually uses cylindrical fabric bags to capture and remove dust and other particles in the air. When the air passes through the dust chamber, particulate matter will collect and accumulate on the surface of the filter. Accumulation improves the efficiency of the filter, allows smaller particles to be collected, and builds pressure on the entire filter cloth. Some bag filters can reach 99.9% efficiency even for small particles. These types of filters are suitable for filtering air pollutants in various industrial processes, including power plants, metal processing centers, and foundries, as well as part of a multi-stage cleaning system.

The accumulation of particles and the resulting pressure difference prompt the need for regular cleaning. The bag filter room uses a variety of methods to remove the accumulation in the filter bag, including;

Shake the filter bag

Introduce the airflow into the filter bag in the opposite direction to the filtration process

Blow compressed air into the filter bag in the opposite direction to the filtration process

For any of the above cleaning methods, the particles will fall from the filter cloth to the bottom of the dust chamber shell and enter the collection funnel for subsequent treatment and disposal of the pollution control system selection considerations.

Although there are a variety of air pollution control systems and equipment and systems available, the suitability of each type in reducing the emissions of chemicals, vapors, and dust into the atmosphere, as well as filtering and purifying the air in the working environment depends on several factors.