Industrial waste gas treatment equipment is also known as scrubbers, waste gas treatment towers, spray towers, waste gas absorption towers, and waste gas scrubbers. Wet swirl plate exhaust gas purification tower is more advanced in wet dust removal technology. The effect of dust removal, desulfurization, and spray paint removal on boilers is particularly significant. It is also widely used. Compared with other wet processes, the dust removal effect is better. lower. It not only removes more than 95% of paint dust but also ensures low gas humidity and simple water filtration.

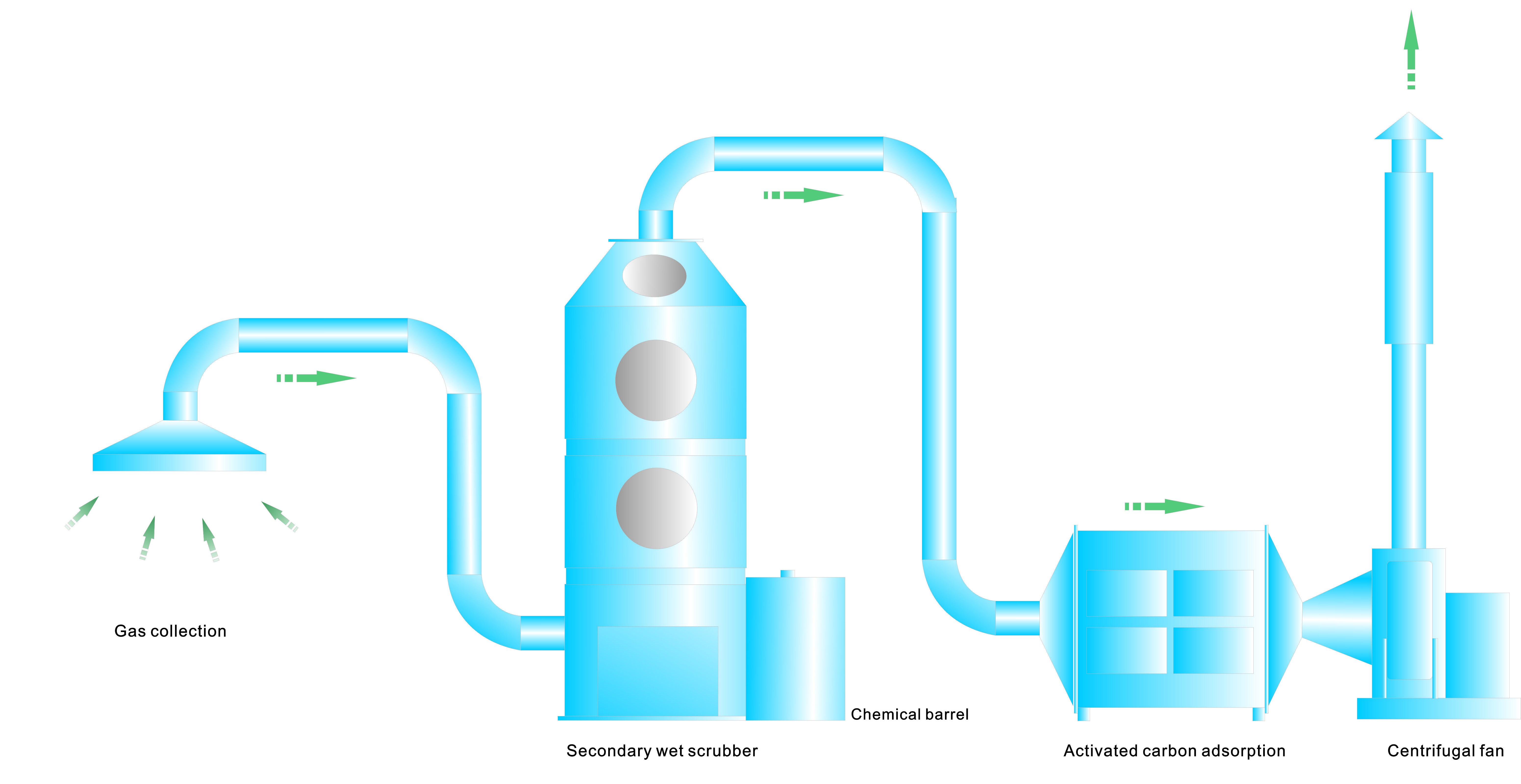

The working principle of industrial wet scrubbers can be divided into three forms: co-current, counter-current, and cross-current. Among them, the most commonly used is countercurrent spraying: acid or alkaline acid mist waste gas is introduced into the purification tower through the air duct, passes through the packing layer, and the waste gas is fed from the bottom of the tower. continuous through the voids of the packing layer. On the surface of the filler, the gas-liquid two phases are fully contacted to absorb and neutralize the reaction to adsorb the acidic or alkaline pollutants contained in the exhaust gas. After the acid mist exhaust gas is purified, the clean gas is discharged from the fan into the atmosphere after dehydration and demisting by the defogging plate. Insoluble viscose particles and dust are poured into the collection tank, suspended particles are discharged from the overflow outlet, and the collected sediment is discharged from the sewage outlet. The absorption liquid is pressurized by the water pump at the bottom of the tower and sprayed down at the top of the tower, and finally refluxed to the bottom of the tower for recycling.

When selecting industrial waste gas treatment equipment, it is necessary to consider its technical principles, structure, accuracy, productivity, process equipment, etc., which ultimately depend on the needs of the production process. Industrial waste gas treatment equipment pollutes the surrounding environment caused of waste gas, waste liquid, waste, and noise during the production process. These reports should contain detailed methods and technical measures on how to control these pollution sources, as well as predict the degree of impact on the environment. The following points need to be considered.

Design a safe and reliable industrial waste gas treatment device according to the nature of the waste gas (viscosity, temperature, humidity, pressure, flammability, toxicity, stability, gas type, etc.).

The equipment is required to have a simple structure, convenient operation, and easy replacement of absorbents, adsorbents, or catalysts. Our industrial waste gas treatment equipment has high fire-proof and anti-corrosion performance, safe and stable equipment performance, stainless steel material, and an equipment service life of more than fifteen years.

The main consideration is the cost of equipment manufacturing, installation, operation, maintenance, and the treatment of exhaust gas standards, and no secondary pollution should be caused. THY-series industrial waste gas (industrial waste gas) UV photolysis industrial waste gas treatment equipment has no mechanical action, no noise, no special management, and daily maintenance, only regular inspections, the low energy consumption of the equipment, extremely low wind resistance of the equipment <50pa, can be Save a lot of exhaust power energy consumption.

According to the emission standards promulgated by the country and the concentration of waste gas emitted by the pollution source, high-efficiency equipment is selected. If one piece of equipment cannot meet the requirements, multiple pieces of equipment are required for multi-stage treatment. XICHENG EP LTD has 12 years of exhaust gas treatment experience and has 33 production bases in China. The company has a professional technical research and development team, sales team, production, and processing team, and construction and installation team.

The washing tower has low noise, stable operation, and simple and convenient operation; the water-washing waste gas treatment system is cheap and the treatment method is simple; the gaseous, liquid and solid pollution sources can be treated; the system has a low-pressure loss, suitable for large air volume; Type filling layer design to deal with mixed pollution sources. It can treat acid and alkaline waste gas economically and effectively, and the removal rate can be as high as 92% or more.

Electronic industry, semiconductor manufacturing, PCB manufacturing, LCD manufacturing, steel metal industry, electroplating and metal surface treatment industry, pickling process, dye/pharmaceutical/chemical industry, deodorization/chlorine neutralization, combustion exhaust gas SOx/NOx Removal and treatment of other water-soluble air pollutants.