Description

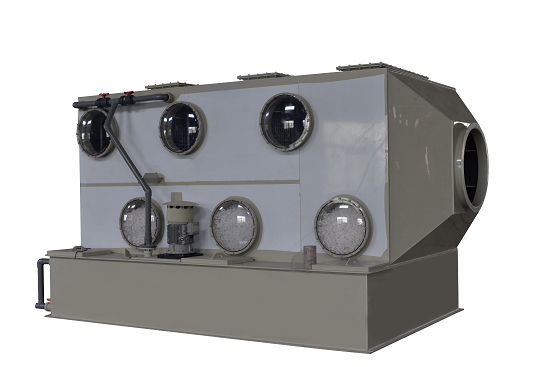

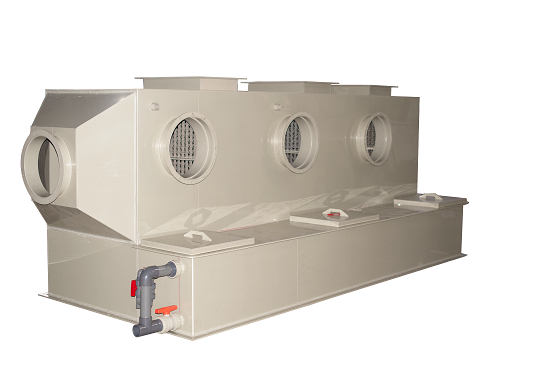

The full name of the horizontal pp polypropylene/stainless steel exhaust gas scrubber is a horizontal crossflow scrubber. Hereinafter referred to as horizontal spray tower. It is suitable for installation in a small space and is mostly used for indoor installation.

1. Equipment introduction:

The horizontal pp polypropylene/stainless steel exhaust gas scrubber is suitable for installation in a small space and is mostly used for indoor installation. It can be used to treat soluble gases, liquid particles, solid particles, and ozone. In industrial use, it can be used as a cooling tower, and humidifier, and is suitable for waste gas treatment in various engineering processes.

2. Structure and working principle

structure

The structure of the horizontal pp polypropylene/stainless steel exhaust gas scrubber: the acid and alkali waste gas is sucked in by the connecting air pipe and passes through the packing layer from bottom to top. The mixed circulating absorbent is sprayed evenly from the top of the tower through the liquid distributor. Into the packing layer, and flow down along the surface of the backing layer, and into the circulating water tank.

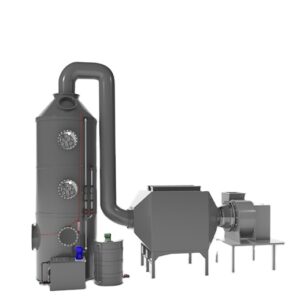

principle

Harmful exhaust gas is forced into or sucked into the air inlet section by the centrifugal fan, then flows to the packing layer, and reacts with the spray liquid. The horizontal pp polypropylene/stainless steel exhaust gas scrubber uses clean water as the circulating absorption liquid, and the circulating water is sprayed from the water distributor on the upper part of the tower to the packing layer to wet the surface of the packing to form a flowing liquid film. The gas and liquid phases in the packing layer are in countercurrent flow, and the gas and liquid phases are in countercurrent contact in the tower body. The certain solubility of the harmful gas in the absorbent is used, and the soluble part is continuously integrated into the absorption liquid to reach the harmful group in the degradation gas. The purpose of sub-content.

3. Features of this equipment:

1. The horizontal pp polypropylene/stainless steel exhaust gas scrubber occupies a small space.

2. Low resistance, low energy consumption, and low noise.

3. polypropylene material has the characteristics of flame retardant, chemical corrosion resistance, and high hardness.

Technical Parameter Table :

1. This form is a common size and we can customize different sizes and requirements according to your needs.

2. The material is polypropylene.

3. Equipment design wind speed 1.8m/s