Description

Product introduction

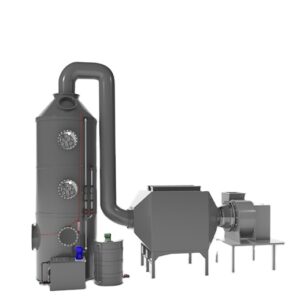

Gas treatment system wet scrubbers are a kind of equipment that can eliminate harmful gases. The scrubber body is made of a high-quality PP sheet, and the packing or tray is installed in the tower.

Working principle

The liquid enters from the top of the scrubber and is sprayed into a mist or raindrop shape through the nozzle; the gas enters from the lower part of the scrubber, and after being dispersed by the packing, it is in close contact with the mist or raindrop-shaped liquid for mass transfer. The soluble components in the gas are absorbed or neutralized and then discharged through the chimney at the top of the scrubber.

Features

The whole is made of PP material, which has the advantages of good corrosion resistance, acid and alkali resistance, simple product structure, low resistance, and convenient operation and maintenance. It has a good treatment effect on industrial waste gas, and is suitable for the treatment of continuous and intermittent exhaust gas; it can purify a variety of pollutants at the same time; it is the main equipment for industrial waste gas treatment and improvement of workshop environment at this stage.

- 1. Strong ability to handle acid mist

The gas treatment system wet scrubber is designed with a large cross-sectional area to ensure that the empty tower flow rate meets the design requirements; - 2. High processing efficiency

- The acid mist stays in the scrubber for a long time, ensuring the time required for acid-base neutralization and high purification efficiency;

- 3. Simple structure

- The industrial air filtration system adopts a backwash structure, which is suitable for small space installation and occupies a small area;

- 4. Stable operation

- The gas treatment system wet scrubber is simple in structure, designed with maintenance and inspection ports, automatic control, and stable operation;

- 5. Low system resistance

- The pressure drop of the gas treatment system wet scrubber gas passing through the packing layer per unit height is small;

-

product structure

The gas treatment system wet scrubber body part contains: a water storage tank, packing layer, spray layer, defogging layer, observation window, base, etc.;

The circulating water part contains a vertical circulating water pump, UPVC circulating water pipeline, PP spiral nozzle, water tank level control, floating ball valve, etc.; The dosing system includes PH online detector, dosing metering pump, dosing mixing barrel, etc.

Product Specifications

The main scope of the application

1. The wet scrubber can be widely used in the purification and treatment of acid and alkaline waste gas discharged in the process of the chemical industry, electronics, metallurgy, electroplating, textile (chemical fiber), food, and machinery manufacturing, and other industries. Such as seasoning food, acid making, pickling, electroplating, electrolysis, storage battery, etc.

2. The wet scrubber can be widely used in the pollution control of lead fume or mercury vapor in printing, battery, non-ferrous metal smelting, military, and other industries, as well as chemical, refining, electroplating, picture tube, printing, and dyeing, pharmaceutical, instrumentation, electronic components, machinery manufacturing Waiting for industrial pickling exhaust gas or other exhaust gas purification.

3. In the field of dust removal, the spray tower can be used as a wet dust collector, especially for occasions where the dust concentration is not high but the gas contains certain toxicity.

Installation method

- 1. Basic positioning of gas treatment system wet scrubber to determine the direction of exhaust gas inlet,

2. Install the front exhaust pipe and connect it to the exhaust inlet,

3. The fan is installed at the back end, and the method of negative pressure extraction is adopted,

4. Chimney installation, installed at the rear of the fan, blowing from the fan into the chimney,

5. The drug-device is installed, and the dosing port is passed into the water tank of the gas treatment system wet scrubber,

6. The electric control device is installed, and the circulating water pump, fan, and dosing device of the gas treatment system wet scrubber are controlled by the electric control panel,

7. Installation of testing port and testing platform,

8. Test the machine, and adjust the air volume and flow rate by adjusting the opening of the front air valve.

Ordering information

- 1. Provides data on the media and concentration of the treated waste gas,

2. Confirm the collection method of exhaust gas and calculate the total treated air volume,

3. Confirm whether the installation space of the polypropylene pp plastic spray tower is sufficient,

4. Confirm the voltage,

5. Confirm whether there is a wastewater treatment system, and waste liquid is produced in the circulating water tank in the polypropylene pp plastic spray tower,

6. Confirm whether there is influent water and whether the polypropylene pp plastic spray tower needs to be supplemented with water. -

Product extension reading

-

What kind of waste gas can the wet scrubber for waste gas purification treat?

The gas treatment system wet scrubber is widely used in the washing and purification of NOX, SO2, H2SO4, HCl, HF, SIF4, CO2, and other toxic and harmful gases generated in the chemical, electroplating, hardware, electrical, pharmaceutical, printing, and dyeing, telecommunications, and other mechanical processing industries; It can also be applied to the deodorization treatment of ammonia, hydrogen sulfide, phenolic, formaldehyde, methanol, amines, and other malodorous substances; the purification area of acid mist exhaust gas depends on the treatment volume, and the neutralization and removal effect is 95%; the discharge port is less than 10PPM. Fans and pumps can be flexibly designed and laid out according to the user’s site, featuring convenient maintenance, compact structure, and a small footprint.

Company Services

-

1. Powerful manufacturers guarantee the delivery cycle

- In the field of chemical anti-corrosion, the integrated service of production, research, and development, design and sales, self-production and self-selling, to benefit customers; source manufacturers, automated production workshops, system management processes, and strict control processes to ensure delivery cycle;

-

2. Quality management Meets standard delivery requirements

- Has a series of quality testing equipment, imported brand raw materials, processed in a dust-free environment, high cleanliness, strong anti-corrosion ability, high temperature, and high pressure, one-time molding, has a thousand-level clean workshop, the entire lining processing, welding process pay attention to no Dusting operation, as far as possible to ensure the quality of plastic welding and equipment life;

-

3. Exclusive design · Born for demand

- The R&D technical team ensures the continuous updating of products; can recommend suitable materials and processes for customers, meet customer non-standard customization requirements, design and transform products accordingly, and match anti-corrosion equipment according to customer application scenarios and equipment;

-

4. Service system · One-to-one full coverage service

- Pre-sale: understand customer needs, and can provide customized anti-corrosion services by testing anti-corrosion equipment; in-sale: on-site service can be provided according to customer needs; after-sale: 7*24 hours customer service, timely access to service requests, and providing fast and effective solutions Solution service;

-

5. Problem feedback · Quick response

- XICHENG EP LTD has an immediate response mechanism, and the technical staff can answer your questions during the operation anytime and anywhere, and we will reply within 24 hours for the content of the website consultation;

-

6. Regular maintenance and operation guidance

- All equipment is guaranteed and maintenance services are provided to save equipment maintenance and operating costs by reducing equipment wear and tear

-

Contact Information

- Email: Leyte@chian-xicheng.com

- WhatsApp: +86 13378669672

- Contact: Lora Wu