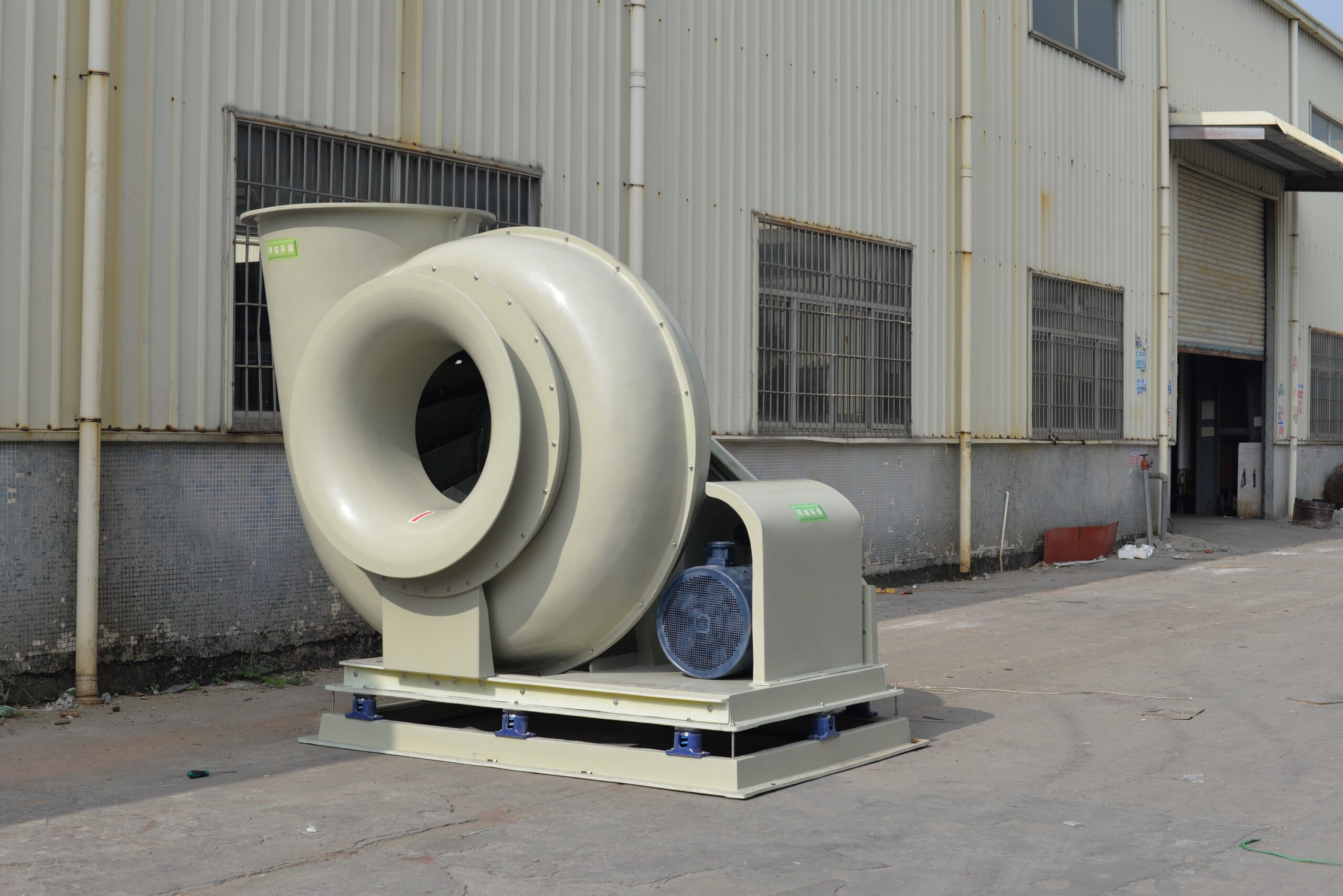

Description

FRP centrifugal blower is made of FRP material, also called an anticorrosive centrifugal fan. Generally, it can be used on occasions with corrosive gas to discharge corrosive gas. The gas conveyed is not allowed to contain viscous substances, dust, and hard particles less than or equal to 150mg/m3, gas temperature less than or equal to 60 degrees, and relative humidity less than or equal to 100%. Fiberglass centrifugal blowers are not suitable for high-temperature places.Features

It has the characteristics of strong anti-corrosion performance, long service life, and stable operation.

Generally, FRP centrifugal blower can be used on occasions with corrosive gas to discharge corrosive gas. The gas conveyed is not allowed to contain viscous substances, dust, and hard particles less than or equal to 150mg/m3, gas temperature less than or equal to 60 degrees, and relative humidity less than or equal to 100%. Fiberglass centrifugal fans are not suitable for high-temperature places.

Working principle

As the name suggests, the FRP centrifugal blower is a centrifugal fan made of FRP anti-corrosion material. The working principle is that when the motor rotates to drive the fan impeller to rotate, the gas between the blades in the impeller also rotates, and is thrown out under the action of centrifugal force. In gas, the gas flow rate increases, so that the gas in the flow converts kinetic energy into static pressure energy, and then as the fluid is pressurized, the static pressure energy is converted into velocity energy, and the gas is discharged through the exhaust port, and it is formed in the middle of the impeller. In order to achieve a certain negative pressure, because the inlet is negative, the outside air is immediately filled under the action of atmospheric pressure, and the gas is continuously discharged and filled under the action of the continuous rotation of the impeller, so as to achieve the purpose of continuous air blowing. Under the same power, wind pressure and air volume are generally inversely proportional. Under the same power, the wind pressure is high, the air volume will be relatively low, and the wind pressure will be lower if the air volume is large so that the power efficiency of the motor can be fully utilized.

Production workshop

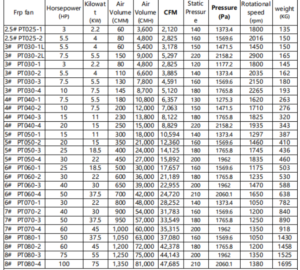

Specifications:

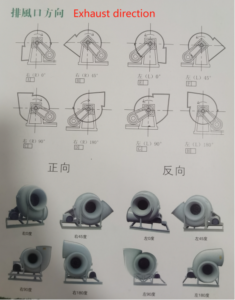

Directions:

Applications:

1. It is suitable for temperature exhausting, air conditioning, acid mist purification, and transportation of acid gas or atmospheric corrosion resistance in chemical, metallurgy, textile, food, medicine, petroleum, and other industries. Can be used as input gas or as output gas. It is especially suitable for use with various types of exhaust gas purification towers. It is the ideal auxiliary equipment for waste gas purification tower;

2. Type of conveying gas: air, acid gas, alkaline gas, corrosive gas;

3. Impurities in the gas: no viscous substances are allowed in the gas, and the dust and hard particles contained in it are not more than 150mg/m3;

4. The temperature of the gas: is less than 80 ℃.

Contact:

Email: leyte@china-xicheng.com

WhatsApp&WeChat: +86 13378669672

Name: Lora