Description

Chemical principle:Using ferrous chloride solution as the absorption liquid, iron as the regenerating agent, the oxidation-reduction reaction between chlorine and ferrous chloride produces ferric chloride, which can be reduced with the regenerating agent. The chemical reaction formula is as follows:

2FeCL2+2CL2=2FeCL3

2FeCL3+Fe=3FeCL2

Advantage:

1. Strong absorption capacity and large capacity. The ferric chloride solution absorbs chlorine to generate ferric chloride (ferric chloride) solution, and the ferric chloride solution reacts with the iron filings in the absorption reaction box to form ferric chloride solution. The concentration of ferric chloride is continuously increased with the absorption of chlorine so that the absorption capacity is enhanced and the capacity is continuously expanded;

2. The absorbent is not aging, has little corrosiveness, does not need to be replaced, and can be continuously recycled.

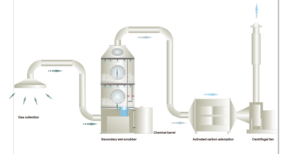

Internal structure and workflow:

The chlorine absorption tower can ensure that the leaked chlorine is absorbed in time and treated in a harmless manner. When there is chlorine leakage, the chlorine leakage alarms installed in the chlorine cylinder room and the chlorination room start to alarm, and transmit the chlorine leakage signal to the chlorine leakage absorption safety device, the device runs automatically, and the fan and pump start to operate. The fan sends the chlorine-containing gas into the absorption tower from bottom to top, and the pump draws the absorption liquid and sprays it from top to bottom. The chlorine-containing gas contacts and reacts in the packing of the absorption tower. After the reaction is completed, the tail gas returns to the chlorine cylinder, the liquid after the reaction is returned to the solution tank, and after regeneration, it is pumped into the absorption tower for reaction and is continuously recycled.

The chlorine absorption tower can effectively control the leaked chlorine gas for treatment in a closed internal system formed by the chlorine cylinder room and the chlorine leakage absorption safety device, without emitting exhaust gas to the atmosphere, and deal with the chlorine leakage accident more thoroughly.

Precautions for the use of equipment:

1. The device should be started twice a month for testing, 10 minutes each time, to ensure that the device is in a normal standby state;

2. Long-term power supply for the control box of the chlorine leakage absorption device must be guaranteed;

3. The chlorine leakage alarm is in good condition and keeps working;

4. The chlorination room and the chlorine bottle room should be normally closed, especially when a chlorine leakage accident occurs, immediately close the doors and windows to prevent the escape of chlorine, and start the device for absorption treatment;

5. When a chlorine leakage accident occurs, in addition, to immediately starting the device for absorption, it is also necessary to find a way to close the leakage source as soon as possible to effectively deal with the chlorine leakage accident;

6. Pumps and fans are in good condition; routine mechanical and electrical maintenance should be carried out at ordinary times to ensure that they can be put into operation at any time;

7. The absorption liquid is not corrosive, and a small amount of it sticks to the skin or splashed into the eyes; immediately rinse with plenty of water.