Description

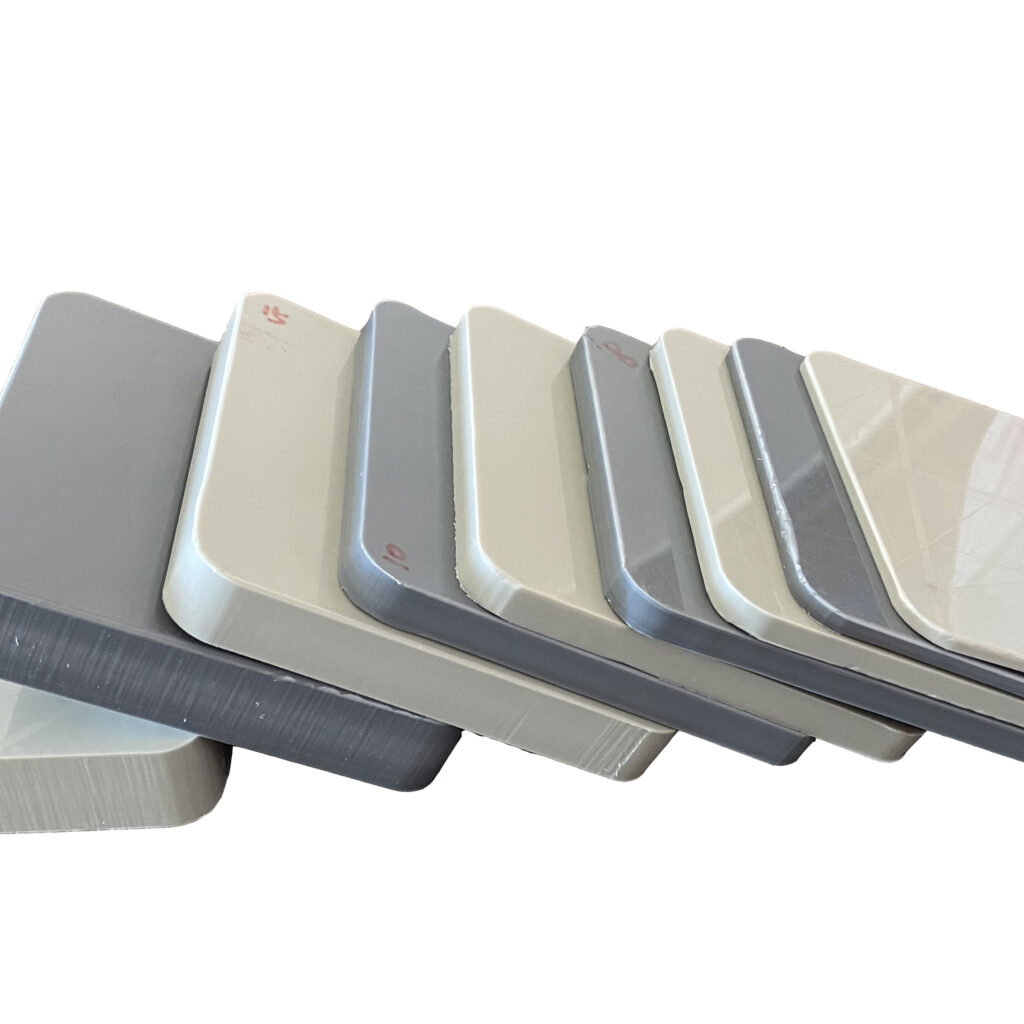

Plastic sheet polypropylene, polypropylene extruded sheet is a plastic sheet made of PP resin added with various functional additives through extrusion, calendering, cooling, cutting, and other processes. PP board is a semi-crystalline material. It is harder than PE and has a higher melting point.Features of pp sheet: With high rigidity, high hardness, and high strength, PP material can withstand tensile stress and is easy to weld, becomes brittle at low temperature, is chemically stable, and has excellent electrical functions. The working temperature ranges from 0 degrees to 100 degrees.

PP sheet characteristics: low density, easy to weld and process, superior chemical resistance, heat resistance, and impact resistance, non-toxic and odorless, it is one of the engineering plastics that most meet the environmental requirements.

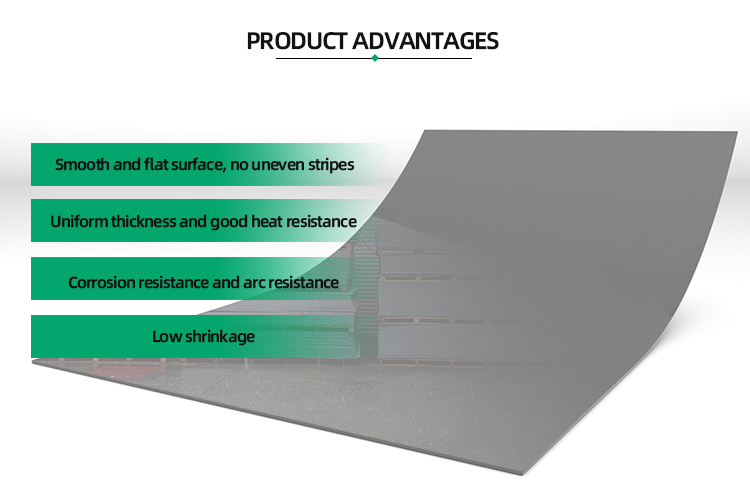

Advantages of plastic sheet polypropylene:

- Chemical inertness: PP is a chemically inert material with excellent corrosion resistance, can be used stably for a long time in many chemical environments, and is not easily corroded and eroded by chemical substances.

- High temperature resistance: PP solid plastic sheet can work at relatively high temperature and has excellent heat resistance. This makes it perform well in some applications that require resistance to high temperature environments, such as hot air ducts, high temperature industrial equipment, etc.

- Good mechanical properties: PP solid plastic sheet has high strength and rigidity while having low density. This makes it a lightweight yet strong enough choice in many structural and mechanical applications.

- Electrical insulation: Due to its good electrical insulation properties, PP solid plastic sheets are widely used in the electronics and electrical fields, such as making battery isolation plates, electrical components, etc.

- Good impact toughness: PP solid plastic sheet has good impact resistance and can perform well in applications that require durability and shock resistance.

- Ease of processing: PP solid plastic sheet can be cut, welded, bent, formed, etc. through various processing methods, and has good processing performance, making it suitable for a variety of customization needs.

- Environmentally friendly: PP is a recyclable plastic material with low environmental impact. It can replace other materials in some environmentally conscious applications.

- Anti-ultraviolet performance: PP solid plastic sheet has good anti-ultraviolet performance and is not easily affected by ultraviolet radiation, so it can also maintain a long service life in outdoor applications.

What occasions is PP suitable for use?

PP sheet is what we often call polypropylene sheet, which is a new type of environmentally friendly material. Generally used in acid and alkali resistant equipment, electroplating equipment, solar photovoltaic equipment, environmental protection equipment, wastewater, exhaust gas discharge equipment, wet scrubbers, clean rooms, semiconductor plants, and related industrial equipment, and it is also a good material for manufacturing plastic water tanks. Among them, plastic plates are widely used in stamping plates, punching mattress plates, and so on.