Description

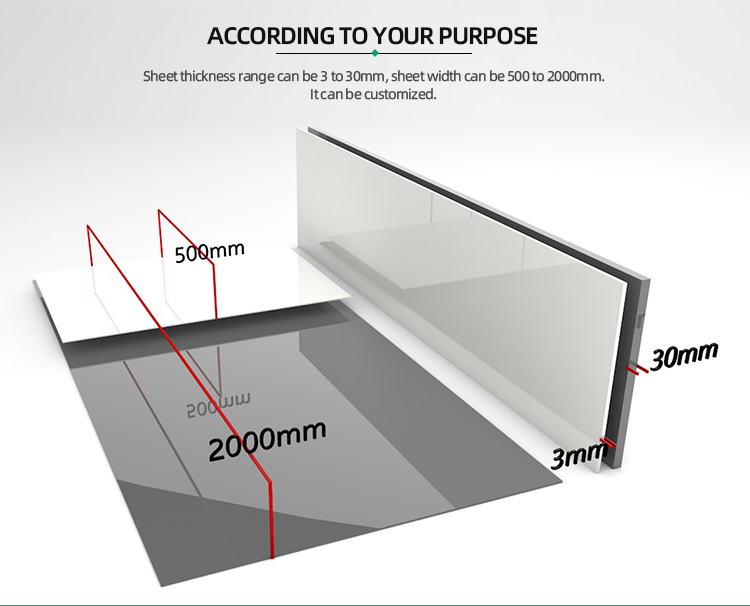

Polypropylene PP is a semi-crystalline material. It is deeper than PE and has a higher melting point. Since the homogeneous PP sheet becomes brittle and easy to break when the temperature is lower than 0℃, many commercial PP sheets add 1~4% ethylene raw material to improve the flexibility of the sheet.

The strength of polypropylene PP increases with the increase of ethylene content. The melting point temperature of polypropylene is 150°C. Due to the increased crystallinity, the board surface and scratch-resistance of this material are very good. PP board is usually used in a corrosion-resistant environment, and the PP is improved by adding glass fiber, metal additives, or thermoplastic rubber.

These plastic sheets can be used in a range of industries and applications, such as:

- Packaging: Polypropylene sheets are commonly used in packaging applications due to their durability and resistance to moisture and chemicals. They can be used for creating boxes, trays, containers, and more.

- Signage: The sheets can be used for creating durable outdoor and indoor signs, banners, and displays. They are often chosen for their weather resistance and printability.

- Construction: These sheets can be used for making temporary walls, partitions, and barriers due to their lightweight nature and ease of installation.

- Industrial: In industrial settings, these sheets can be used for various purposes including machine guards, protective covers, and components for machinery.

- Art and Craft: Artists and craft enthusiasts use polypropylene sheets for projects like stencils, templates, and other creative applications.