The PP caustic washing tower is a kind of waste gas treatment equipment, which is usually used for the purification treatment of industrial acid and alkali waste gas. Among them, the acid mist waste gas is more used, so it is also called the acid mist absorption tower. The PP caustic scrubber produced can not only treat acid mist waste gas but also other waste gas, such as ammonia (NH3), hydrogen sulfide waste gas, VOC organic waste gas, domestic waste gas, and waste combustion waste gas.

This article explains the structure and working principle of the PP caustic scrubber. When the PP caustic scrubber is used to treat acid mist exhaust gas, under the action of the anti-corrosion exhaust fan, the acid mist exhaust gas is introduced into the PP caustic scrubber through the PP air pipe and passes through the packing. Layer, the acid mist and sodium hydroxide absorbing liquid are in full gas-liquid contact, and acid-base neutralization reaction and absorption occur. After the acid mist exhaust gas is purified, the PH value reaches the set value and then passes through the multi-faceted hollow ball demisting layer The filler is discharged into the atmosphere by the fan after dehydration and demisting. The anti-corrosion exhaust fan here is rear-mounted, that is to say, it is suction air. The absorbing liquid falls on the bottom of the tower and is pressurized by the water pump and then returns to the top of the tower to continue to circulate and spray down. The purified acid mist exhaust gas meets the emission requirements of the emission standard, which is lower than the national emission standard.

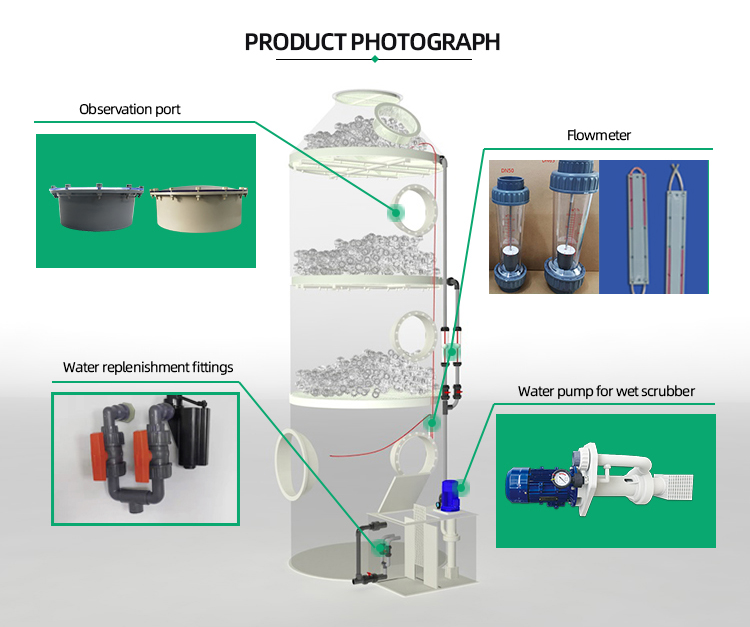

Demisting layer: Generally separated by grid plates, the filler is placed on it, and the height of the filler layer can reach 500mm. In order to improve the efficiency of defogging, the PP caustic washing tower produced can be equipped with a plate-type mist eliminator.

Spray layer: The spray layer is composed of spray pipes and nozzles. According to the diameter of the PP caustic washing tower, the density of the spray pipes and nozzles is different. Using high-efficiency nozzles, the spray is even and the flow is large and not easy to be blocked.

Packing layer: The packing layer is placed on top of the defogging layer and sprays layer. The main fillers are multi-faceted hollow balls and Raschig rings. The packing layer in the PP caustic washing tower is used as the mass transfer equipment for the contact components between the gas and liquid phases. The bottom of the packing tower is equipped with packing support plates, and the packing is placed on the support plates in a random pile. A packing pressure plate is installed above the packing to prevent it from being blown by the rising airflow. The spray liquid of the PP caustic washing tower is sprayed onto the packing from the top of the tower through the liquid distributor and flows down the surface of the packing.

Window: It is also called the detection port. Usually, the formed window has two specifications of φ500mm and φ400mm. The main function of the window is to observe the operation of the PP caustic scrubber, replace the packing, and repair the nozzle.

Live connection ball valve: mainly to control the switch of circulating water.

In addition, the circulating water tank is also an important part of the PP caustic washing tower. The water tank can be flexibly set up and connected or not connected to the body of the PP caustic washing tower.