Industry Introduction

Most factories have their own injection molding workshops, and the plastic waste gas produced by them must meet the national second-level emission standards before it can be discharged. At present, there is a mixed bag of equipment for treating plastic waste gas on the market. It is not easy for customers to choose a set of waste gas treatment equipment suitable for their own factories according to the injection plastic waste gas treatment plan.

Industry characteristics

The exhaust gas components produced by the plastics industry mainly include non-methane total hydrocarbons, benzene, toluene, ethylbenzene, styrene, o-xylene, meta-xylene, n-undecane, acetone, methyl ethyl ketone, is acetone, and ethyl acetate. , Butyl acetate, etc. Different plastic product industries have different exhaust gas components according to different processing techniques and raw materials. In addition to waste gas, there may be obvious particulate matter and flue gas in some plastic processing processes.

—————————————————▶Way design planning◀———————————————————

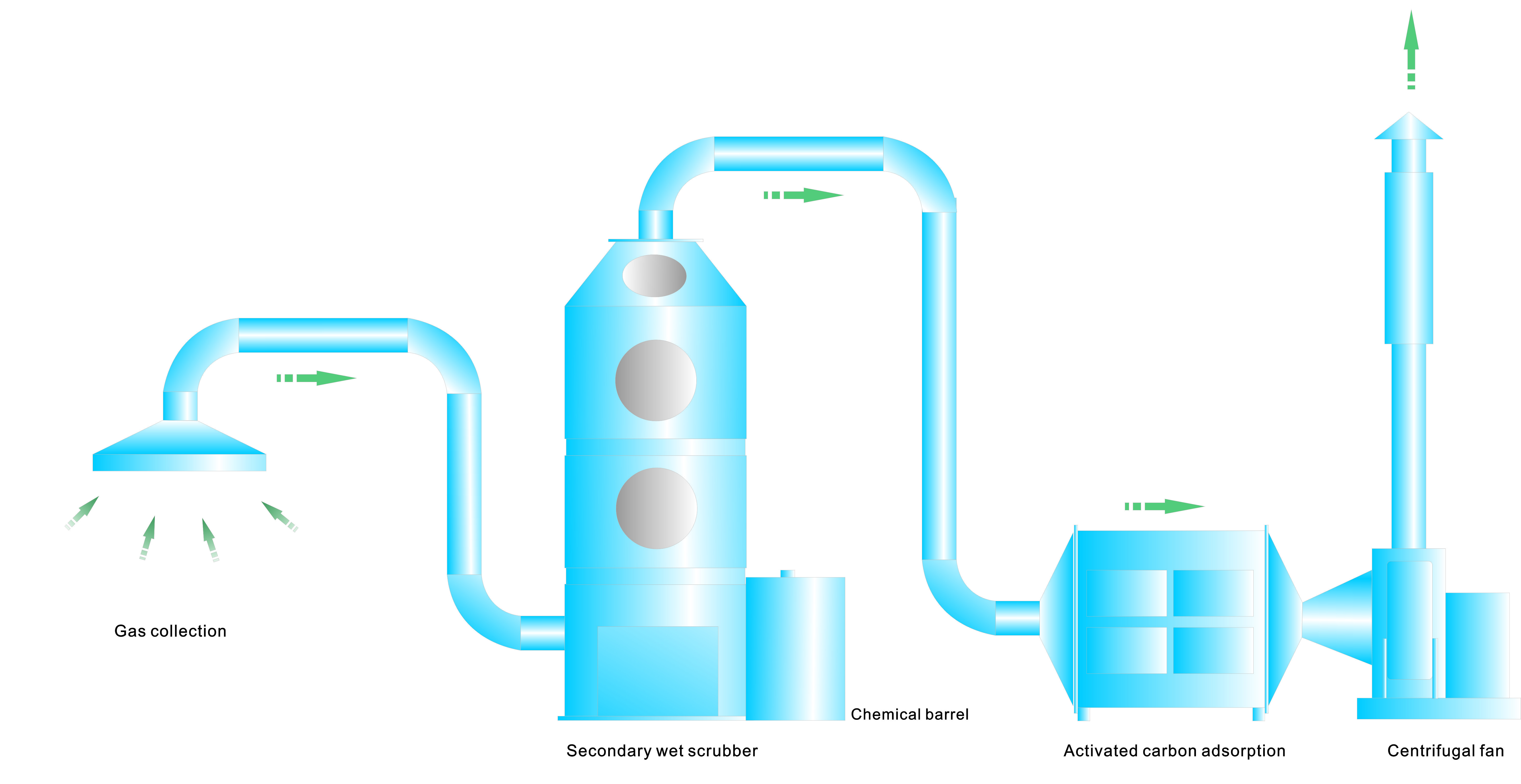

Wet scrubber + Activated carbon adsorption treatment + Centrifugal fan

Brief description of the recommended treatment process:

Oxidatively crack 75% of the exhaust gas into harmless CO2 and H2O. The remaining part of the exhaust gas passes through the activated carbon adsorption equipment and then undergoes the adsorption treatment of activated carbon so that the exhaust gas meets the emission standards.

Plastic waste gas is produced in the process of drawing and granulating heating. There is a certain amount of white glue fumes during the process of dissolving plastic and cooling the granulator. The glue smell has a high concentration and is easy to drift away from the flow of the atmosphere. Therefore, it must be collected through an air-collecting hood. It enters the waste gas scrubber through the branch pipe and the main pipe, is further cleaned and treated by the wet cyclone waste gas tower, and then enters the activated carbon adsorber through the pressurized induced draft fan. The organic gas is adsorbed by the activated carbon in the bed. The activated carbon is suitable for large flow and low concentration. For organic waste gas, activated carbon adopts granular activated carbon with a specific surface area (adsorption area) of up to 500-1500m2/g. The specific surface area is large, so the activated carbon in the activated carbon adsorber has a high surface activated carbon adsorption capacity. The discharged low-concentration organic gas is adsorbed on its active surface and the purified gas is discharged at a high altitude from the external exhaust pip