The laboratory fume hood scrubber is made of PP polypropylene material, and the inner packing is a PP Pall ring or a hollow sphere. According to the gas-liquid two-phase mass transfer reaction on the surface during the gas absorption process, the transfer rate is proportional to the specific surface area. Therefore, the filler is used to increase the specific surface area of the two phases, so that the two phases are in full contact, and to achieve the purpose of absorbing or purifying exhaust gas.

Principle and structure of purification and absorption equipment for laboratory fume hood scrubber

The laboratory fume hood scrubber itself includes the body, filling layer, defogging layer, circulating sprinkler, etc., with exhaust gas inlet, outlet, washing liquid inlet, overflow, drain, filling material, circulating water pump, circulating water filter, circulating water pipeline, Sprinkler nozzles, windows, maintenance holes and the internal structure of the scrubber to support and fix the structure; the tower body is made of PP, PVC, etc., to ensure the corrosion resistance of the equipment itself to increase its service life. Objects of use: Treatment of liquid particles, solid particles, heavy metal harmful substances, organic solvents, odors, and water-soluble air pollutants in various manufacturing waste gas and various laboratory waste gas.

The fume hood scrubber is a new type of environmental protection equipment. The role of the scrubber is to remove impurities in the gas with a solvent. It can be used in various industries that produce gas that needs to be scrubbed. For example, a sulfuric acid production line will produce gas with impurities such as mineral dust, arsenic, selenium, fluorine, sulfur trioxide, etc. The gas enters the tower and fully contacts the scrubbing liquid in the tower to remove impurities and achieve the role of gas purification.

The working principle of the most commonly used industrial wet scrubber is countercurrent spraying: acid or alkaline acid mist exhaust gas is introduced into the purification tower through the air duct, and the exhaust gas is fed from the bottom of the tower through the packing layer. continuous through the voids of the packing layer. On the surface of the packing, the gas-liquid two phases fully contact, absorb and neutralize the reaction, and adsorb the acidic or basic pollutants contained in the exhaust gas.

After the acid mist exhaust gas is purified, the clean gas is dehydrated and demisted by the defogging plate and then discharged into the atmosphere by the fan.

Insoluble viscose particles and dust are poured into the collection tank, suspended particles are discharged from the overflow outlet, and the collected sediment is discharged from the sewage outlet. The absorption liquid is pressurized by the water pump at the bottom of the tower and sprayed downward from the top of the tower, and finally refluxed to the bottom of the tower for recycling.

1. It is made of PP plastic with high flame-retardant properties.

2. Using high-temperature hot-melt welding technology, easy to install.

3. Various specifications and sizes can be customized to meet the needs of different industries.

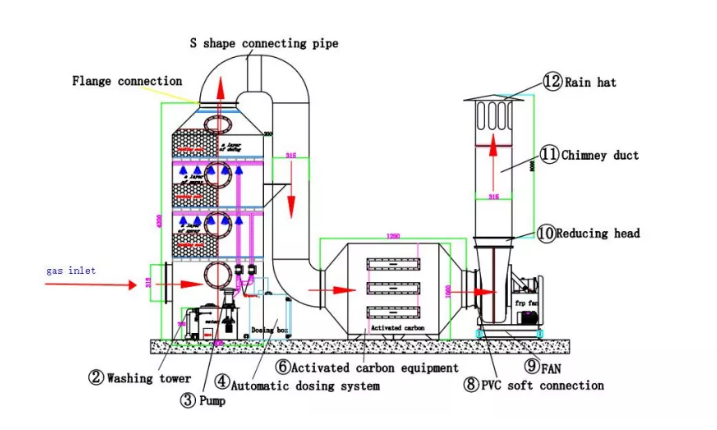

1. Connect the exhaust chimney outlet to the inlet of the washing tower (exhaust gas scrubber);

2. Connect the outlet of the washing tower to the inlet of the activated carbon equipment through the S-shaped connecting pipe;

3. Connect the outlet of the activated carbon equipment to the inlet of the centrifugal fan through the PVC soft connection;

4. Connect the outlet of the centrifugal fan to the chimney duct through the reducing head;

5. The exhaust gas will be purified by the washing tower, and then enter the activated carbon equipment through the S-shaped connecting pipe for adsorption, so as to obtain clean gas, which will enter the atmosphere through the centrifugal fan and chimney duct.

Shenzhen Xicheng Environmental Technology Co., LTD. is located in Guangming District, Shenzhen. It is an environmental protection equipment manufacturer which has been focusing on the environmental protection industry for many years and specializing in the production and sales of environmental protection equipment and various accessories.

With the aims of “Quality First, Mutual Benefit, Cooperation, and Win-Win”, our company is directed by market demand and has independently developed new varieties to satisfy different industries’ needs for the differences and diversification of plastics.