Wet scrubber is a new type of industrial waste gas treatment equipment, using a new type of PP board material. It is composed of the bottom of the tower and the defogging layer. The gas flows from the bottom of the tower to the top through the packing layer and spray layer, and the spray sprinkler goes from top to bottom. Countercurrent neutralization occurs in the packing layer to purify industrial waste gas. It is widely used in industrial waste gas treatment, dust removal, and other advantages. The purification effect is quite good. It is currently the most commonly used and most practical equipment in the treatment of industrial waste gas such as acid-base, spray paint, printing, medicine, hardware polishing, and so on. The PP scrubber has the characteristics of a simple structure, low energy consumption, simple operation, small size, etc., and high purification efficiency. It can effectively remove various industrial organic substances such as HCL, HF, NH3, H2SO4, CrO3, HCN, NAOH, H2S, HCHO, etc. The advantages of waste gas and inorganic industrial waste gas treatment and purification efficiency are high.

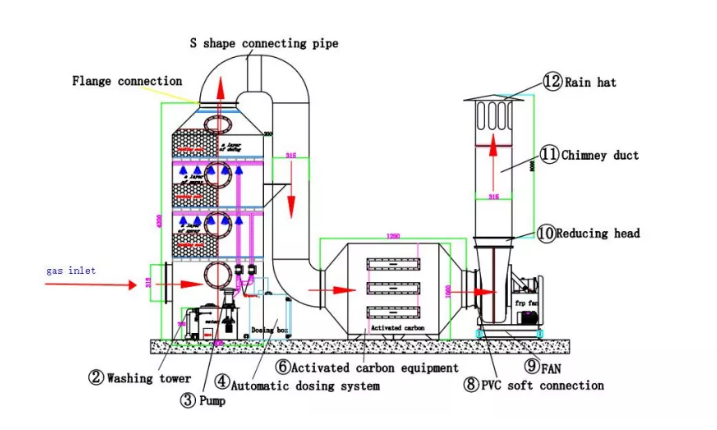

The wet scrubber body contains the exhaust gas inlet, packing layer, spray sprinkler, defogging layer, window, discharge port, maintenance port, and wet scrubber for support and fixation.

The industrial waste gas enters the wet scrubber and fully contacts the scrubbing liquid in the tower to produce changes to achieve the treatment and purification effect, which can remove impurities and dust, purify the gas, and finally meet the emission requirements. The purification tower as a whole includes a tower body, a packing layer, a defogging layer, a circulating sprinkler pipeline, and a circulating water tank.

Features

1. Wet scrubber has the advantages of low noise, stable operation, simple operation, and low cost;

2. High efficiency of dust removal and desulfurization, using acid and alkali to neutralize the gas, etc.,

3. Using high-quality PP board, corrosion-resistant, wear-resistant, and long service life, the wet scrubber can be customized according to the air volume of the fan;

The wet scrubber body contains an exhaust gas inlet, packing layer, spray sprinkler, defogging layer, window, discharge port, maintenance port, and PP scrubber for support and fixation. The industrial waste gas enters the tower and fully contacts the scrubbing liquid in the tower to produce changes to achieve the treatment and purification effect, which can remove impurities and dust, purify the gas, and finally meet the emission requirements.

1. Check the dosage of the neutralization medicine every day, carefully record and formulate the dosage calculation and replenish it in time;

2. Check the operation of the water pump every day and check whether the spray nozzle is normal;

3. Check the operation of the fan, the temperature of the motor and the bearing seat, and the noise and vibration of the fan every day;

4. Check and adjust the belt tension weekly, and replace the motor belt quarterly;

5. Change the special oil for the bearing seat within one month of the first use of the fan, and change it regularly every quarter thereafter;

6. Inject high-quality grease into the motor every quarter;

7. Replace the water circulating fluid every month or 15 days regularly. The circulating fluid should be prevented from being saturated, the sediment should be removed in time, and the water tank should be kept clean;

8. Monthly or regularly check the packing for fouling, impurities, or damage.

9. Clean the floating objects in the water tank every month or regularly to reduce the blockage of the water pump.

10. Replace the probe (referring to the dosing pump) every six months, and complete the system matching items according to the specifications and models provided by the original supplier.

11. Replace the packing every year or regularly to prevent aging of the packing and a large amount of adhesive;

12. Check the wear condition of the pump and the smoothness of bearings, gaskets, and operation.

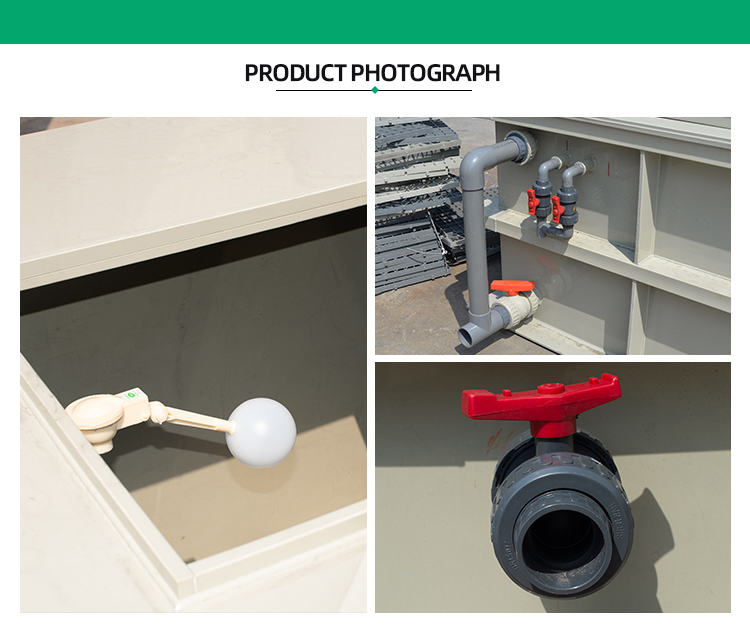

1. If automatic water replenishment is used to replace circulating water, synchronize the adjustment of the drainage adjustment valve and manual water replenishment switch to keep the water replenishment and drainage in balance.

2. The operator should manually replace the circulating water according to the volume of the water tank and the amount of water inflow.

1. Abnormal static pressure of wet scrubber:

2. Circulation pipeline pressure display abnormal situation:

3. Excessive droplets discharged from the outlet of the wet scrubber:

4. The water tank of the washing tower is leaking and the pipe and the tower body are leaking: