The working principle of the wet scrubber is to neutralize the acid-base exhaust gas by means of water hydration, so it is necessary to select different chemical agents according to the acidity and alkalinity of the discharge before use.

1. Alkaline solution

Alkaline absorbents usually contain 1%~10% sodium hydroxide solution, which has a significant effect on eliminating hydrogen sulfide waste gas. Others such as methyl mercaptan, methyl sulfide, methyl disulfide, and lower fatty acids often cause odor in wastewater treatment plants. The treatment effect is also very significant for flavor substances.

2. Acidic solution

Acid liquid washing is mainly used to eliminate the odor caused by alkaline gases such as ammonia and trimethylamine. Generally, sulfuric acid (0.5%-5% solution) is used as the washing liquid.

3. Sodium hypochlorite solution

Sodium hypochlorite is generally used together with acid-base absorbents. For methyl sulfide that is difficult to eliminate by other methods, the control effect of sodium hypochlorite absorbent is very good.

When dealing with high-concentration odors, the concentration of sodium hypochlorite solution (effective chlorine concentration) is about 500-2000 ppm; when dealing with lower-concentration odors, the concentration of sodium hypochlorite solution is about 50-500 ppm. In terms of the performance of various oxidants, sodium hypochlorite is the cheapest and has a good treatment effect, so it is widely used. The sodium hypochlorite in the solution is in the form of hypochlorous acid (HOCl):

NaOCl+ H2O→HOCl+ NaOH

At pH=7.5, the available chlorine of the hypochlorite solution exists as 50% HOCI and hypochlorite ion (OCl-);

At pH=l0, only 0.3% of available chlorine exists as HOCl;

pH=l1 or 12, HOCl is almost completely dissociated into useless hypochlorite ions, so the pH control is very heavy.

The working principle of the most commonly used industrial wet scrubber is countercurrent spraying: acid or alkaline acid mist exhaust gas is introduced into the purification tower through the air duct, and the exhaust gas is fed from the bottom of the tower through the packing layer. continuous through the voids of the packing layer. On the surface of the packing, the gas-liquid two phases fully contact, absorb and neutralize the reaction, and adsorb the acidic or basic pollutants contained in the exhaust gas.

After the acid mist exhaust gas is purified, the clean gas is dehydrated and demisted by the defogging plate and then discharged into the atmosphere by the fan.

Insoluble viscose particles and dust are poured into the collection tank, suspended particles are discharged from the overflow outlet, and the collected sediment is discharged from the sewage outlet. The absorption liquid is pressurized by the water pump at the bottom of the tower and sprayed downward from the top of the tower, and finally refluxed to the bottom of the tower for recycling.

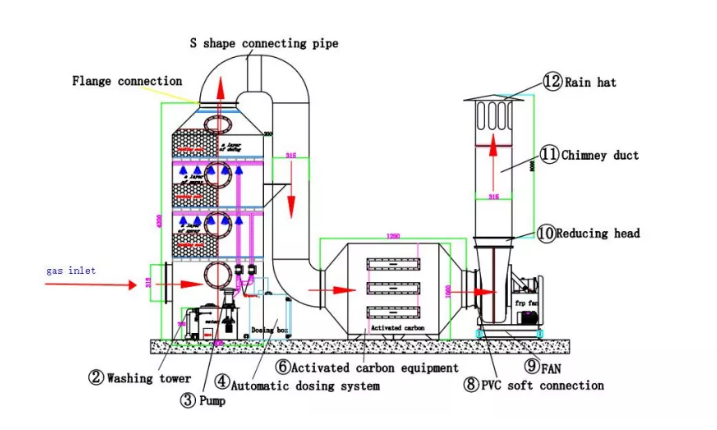

1. Connect your exhaust chimney outlet to the inlet of the washing tower (exhaust gas scrubber);

2. Connect the outlet of the washing tower to the inlet of the activated carbon equipment through the S-shaped connecting pipe;

3. Connect the outlet of the activated carbon equipment to the inlet of the centrifugal fan through the PVC soft connection;

4. Connect the outlet of the centrifugal fan to the chimney duct through the reducing head;

5. The exhaust gas will be purified by the washing tower, and then enter the activated carbon equipment through the S-shaped connecting pipe for adsorption, so as to obtain clean gas, which will enter the atmosphere through the centrifugal fan and chimney duct.