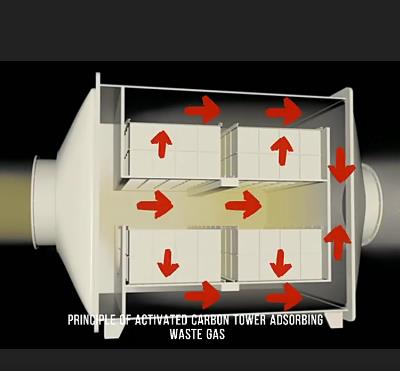

Principle of Contamination

The activated carbon adsorption method is a widely used method of VOC treatment due to low initial investment. It adsorbs VOCs through the natural adsorption capacity of activated carbon. When the adsorption is saturated, the activated carbon is desorbed and regenerated or handed over to professional hazardous waste companies for disposal.

Actual application

Environmental protection companies that use activated carbon adsorption to treat VOCs will basically mention that the decontamination efficiency of such equipment reaches more than 90% in the decontamination parameters of their equipment, but in the actual decontamination application process, the decontamination efficiency reaches 90%. The above are only theoretical values. And under different working environments, its decontamination efficiency is far lower than this theoretical value. The main reasons include the interaction between temperature, working environment humidity, water mist, acidity, dust, and adsorbed gas. For example, the southern part of my country has high humidity and high temperature throughout the year, and its actual adsorption capacity of activated carbon is less than 50% of the laboratory.

Main problem

The actual operation and maintenance cost of using the activated carbon adsorption method to treat VOCs meeting the emission standard is very high. At the same time, it is difficult to manage natural absorption and desorption, and its applicability is affected by many factors. Up to standard. Moreover, the treatment of a large amount of saturated activated carbon is more expensive. This method only transfers pollutants. If there is no strict monitoring and tracking of the activated carbon transfer process after saturation, it is very easy to cause secondary pollution. However, due to the small initial investment, enterprises naturally choose more. Although it is difficult to supervise (there is no activated carbon in the carbon box, the activated carbon facilities are too simple, almost no carbon replacement, the selection of activated carbon does not match the actual design, the amount of use is too small, etc.), but the environmental protection department Some action will eventually be taken, and there is a huge environmental risk. And it is easy to fake and copes with environmental management. (For example, there is no activated carbon in the carbon box, the activated carbon facilities are too simple, almost no carbon replacement, the actual project, and design of activated carbon are not in line with the design, the amount of use is too small, etc.