Industrial waste gas treatment scrubbers have high purification efficiency, good corrosion resistance, lightweight, high specific strength, small footprint, and large waste gas treatment capacity. It is suitable for washing acidic waste gas, alkaline waste gas, and polluted flue gas in incinerators. The washing purification effect can reach 99% so that the gas emission after washing and purification meets the requirements of the “Comprehensive Emission Standard of Air Pollutants.”

China Xicheng Environmental Protection uses polypropylene (PP) as the primary material to produce various specifications of scrubbers, such as horizontal scrubbers, vertical scrubbers, spray scrubbers, exhaust gas purification towers, etc. The system is widely used in acid and alkali waste gas treatment systems and has corrosion resistance. They are mainly used in waste gas treatment projects in semiconductors, PCBs, chemicals, electroplating, printing plants, laboratories, chemical industries, and other industries. Adopting international standard design, fine production, planning, and designing entirely according to your needs, customized products using vinyl saturated resin raw materials, the product’s surface has been treated with enhanced hardness and ultraviolet aging. Its supporting electrical appliances all adopt automatic protection facilities, which are fully adapted to 24-hour uninterrupted operation, and are especially suitable for large-scale continuous production enterprises with high requirements.

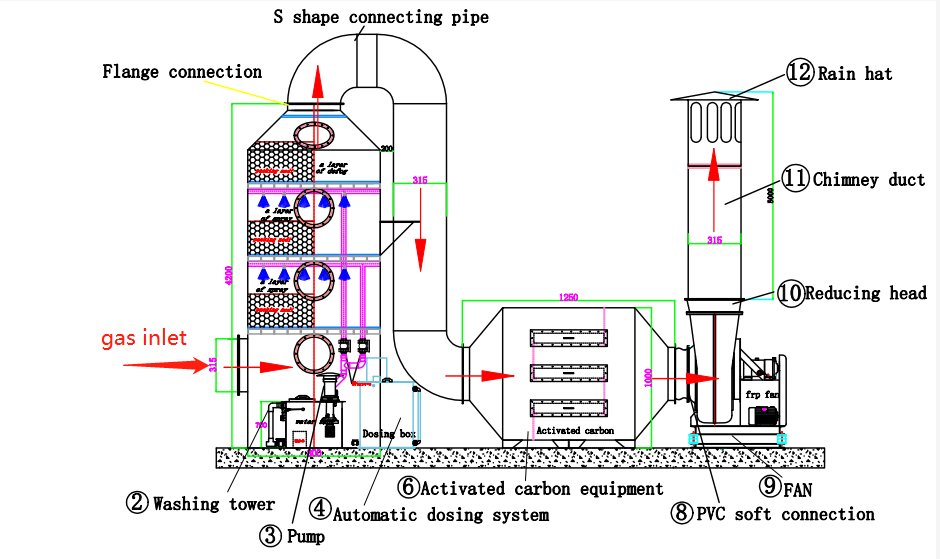

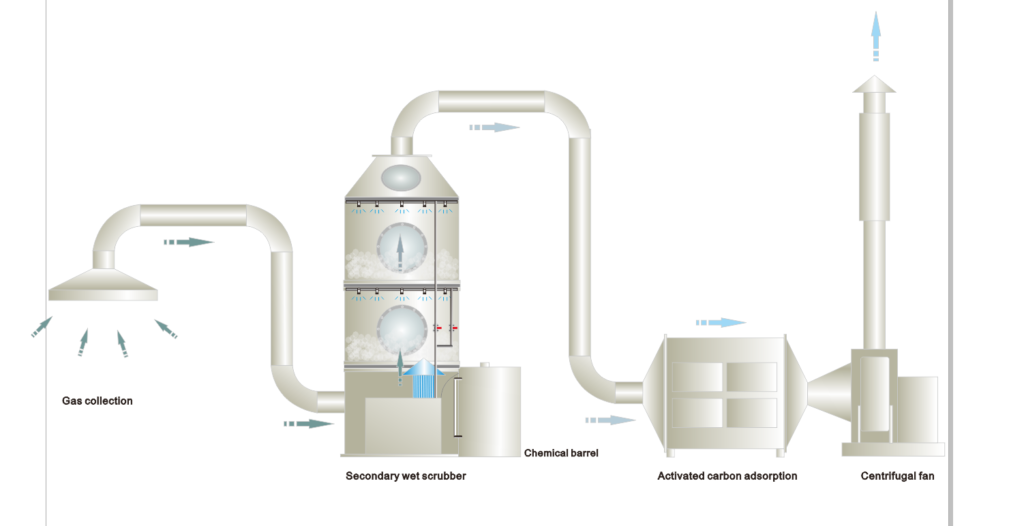

Industrial waste gas treatment scrubber is a new type of gas purification treatment equipment. The scrubber is composed of a tower body, trays, reboiler, and condenser. It is developed based on the floating packing layer gas purifier. It is widely used in the pretreatment of industrial waste gas purification and dust removal, and the purification effect is perfect. For the coal gasification process, gas washing is inevitable, and this unit operation is used regardless of the coal gasification technology. Because its working principle is similar to the washing process, it is named washing tower. The scrubber is identical to the rectification tower, consisting of a tower body, trays, reboiler, and condenser. Since the scrubber is a device for rough separation, the number of trays is generally small, usually not more than ten stages. The scrubber is suitable for the break of mixed gas containing a small amount of dust. The components will not react, and the product should be easy to liquefy. Impurities such as dust (also called high boilers) are not easy to melt or solidify. When the mixed gas is passed into the scrubber from the middle of the scrubber, due to the product component liquid between the trays, the product component gas is liquefied while evaporating part, and the impurities cannot be liquefied or solidified when passing through the trays with liquid It will be fixed by the product component liquid to produce a washing effect. The scrubber is designed and manufactured according to this principle.

The basic principle of industrial waste gas treatment scrubber is to contact gas and liquid to transfer the gas’s pollutants to the drink. The packing spray absorption tower is produced with PP as the primary material, and the packing is made of PP material Pall ring or hollow ball. According to the gas absorption process at the gas-liquid two-phase interface, the transfer rate is proportional to the interface area, and the filler is used to increase the contact area of the two phases so that the two steps are fully dispersed. Then the clean gas and the contaminated Liquid separation achieve the purpose of purifying the air.

The gas is forced into the uniform pressure chamber of the purification tower by a fan, first enters the bubbling section for bubbling treatment, and then passes through multi-stage packing, spraying, and spraying treatment to make the gas-liquid two-phase fully reverse contact to cause neutralization and absorption reaction, and then move forward. To the packing layer, it reacts with the spray liquid. According to the gas purification conditions and other indicators, a third-stage packing and spray device can be installed. After entering the liquid removal device, the liquid is discharged into the atmosphere, and the treated gas reaches National emission standards.

This product is suitable for the chemical industry, machinery, electronics industry, semiconductor manufacturing, PCB manufacturing, LCD manufacturing, steel metal industry, electroplating and metal surface treatment industry, pickling process, dyes, pharmaceuticals, chemical industry, deodorization, instrumentation, etc. Industry electroplating, pickling, corrosion, and other acid mist exhaust gas purification treatment.