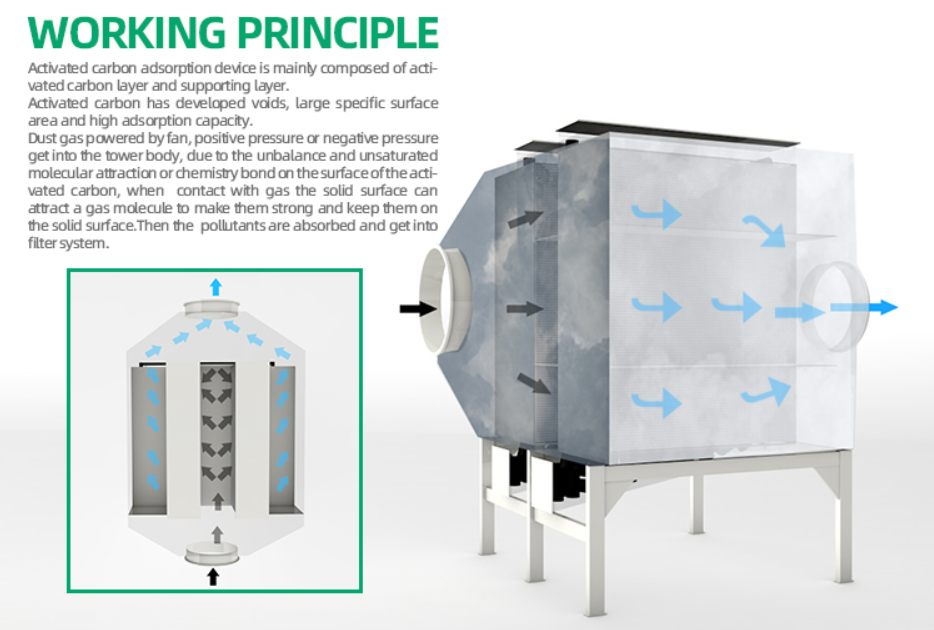

Activated carbon adsorption tower is a kind of equipment commonly used to treat pollutants in gas or liquid. Its principle is to use the highly porous structure and adsorption performance of activated carbon to remove target pollutants. The following is the working principle of activated carbon adsorption tower:

Adsorption principle: Activated carbon is a porous material with a large surface area and abundant tiny pores. As pollutants pass through the activated carbon bed, the pollutant molecules attach to the surface of the activated carbon instead of chemically reacting. This physical adsorption process is called adsorption, in which the pores of activated carbon act as an adsorbent, trapping pollutant molecules on its surface.

Selective Adsorption: The pore structure and chemical properties of activated carbon allow it to selectively adsorb specific types of molecules. This means that activated carbon can be engineered to be tailored to specific pollutants to achieve higher removal efficiencies.

Saturation and regeneration: Over time, the activated carbon surface will gradually be covered with adsorbed pollutant molecules, resulting in a weakened adsorption capacity. When the activated carbon reaches saturation, it needs to be regenerated. Regeneration can be done by increasing the temperature, low pressure desorption, gas purging, or other methods to release the pollutant molecules adsorbed on the activated carbon and restore the activated carbon to a usable state.

Fields of application: Activated carbon adsorption towers are widely used in various fields, including environmental protection, industrial processes, indoor air purification, and water treatment. Activated carbon adsorption towers can be an effective solution when dealing with volatile organic compounds (VOCs), odors, particulate matter, noxious gases, and other pollutants.

Xicheng Environmental Protection, an enterprise deeply engaged in environmental protection equipment manufacturing!