The gas and liquid inside the wet scrubber operate in countercurrent flow. The exhausted waste gas enters the tower body from the bottom inlet of the tower, passes through the packing layer from bottom to top, and is then discharged from the outlet of the tower top pipeline through the anti-corrosion fan. The neutralizing material passes through the liquid distributor at the top of the tower and is evenly sprayed into the packing layer. It moves downwards along the surface of the backing layer to the bottom of the tower, is discharged out of the tower by the pipeline, and is circulated by the anti-corrosion circulating pump. As the ascending exhaust gas and descending absorbent are in constant contact in the packing layer, the concentration of solute in the ascending airflow is getting lower and lower, and when it reaches the top of the tower, it has reached the absorption requirements and discharged out of the tower. On the contrary, the concentration of the medium in the descending liquid is getting higher and higher, and the process conditions are met when it reaches the bottom of the tower and is discharged outside the tower.

The scrubber body is made of anti-corrosion PP, stainless steel, and PRP, which is resistant to aging and has a good appearance.

The spray system is composed of a pipeline (road) spray frame and nozzle. The pipeline (path) and the spray frame are welded by forming PVC pipes, the nozzle adopts a multi-layer spiral type non-clogging nozzle, and the material is PVC or PP. The nozzle is designed and produced according to the standards of the German Enhanced Plastics Association (AVK). It has the characteristics of large flow, uniform spraying, large spraying area, and non-clogging.

The packing in the tower can provide a large enough surface area to promote full contact with the gas phase: a larger specific surface area; a higher mass transfer rate; good moisturizing performance conducive to the uniform distribution of gas and liquid; better porosity, Gas-liquid passing capacity, and airflow resistance are small; high mechanical strength, corrosion resistance, easy to clean and not easy to break.

Agent Name: alkali absorption tower with dilute sulfuric acid, acid absorption tower with sodium hydroxide.

Use ratio

A. Check and fill up the neutralizing absorbent before use.

B. After calculating the water volume in the circulation box, add dilute sulfuric acid to the alkali absorption tower, add sodium hydroxide to the acid absorption tower, and use a circulating solution with a concentration of 3%-6%. Note that the mixing tank should be mixed before adding. Note that if the circulating fluid has crystallized, please discharge and replace it in time.

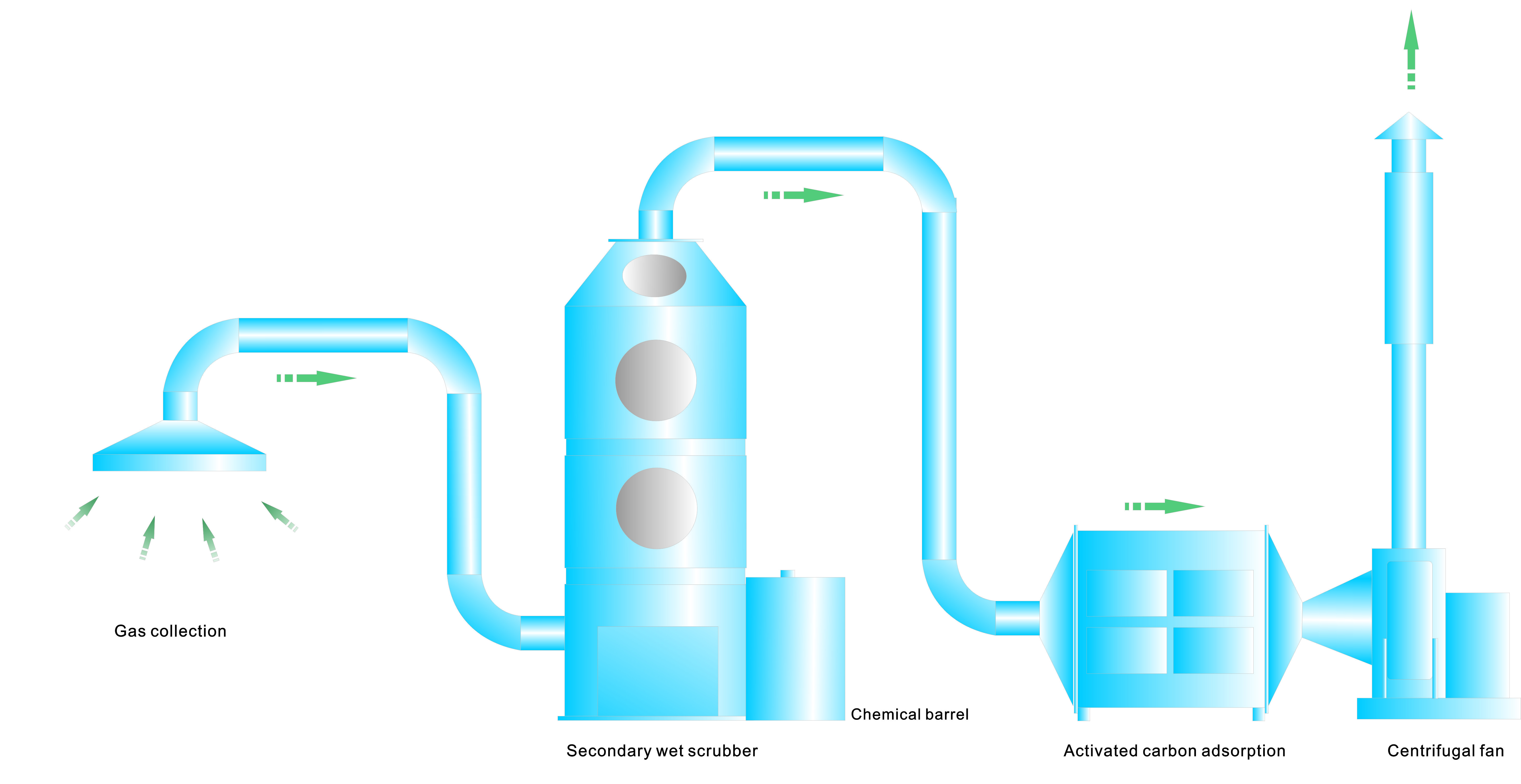

The specific process of acid and alkali waste gas treatment: the removed acid mist waste gas → enters the air duct → and passes the acid-base wet scrubber purification treatment → fan → air duct → discharge up to standard.

Acid-base waste gas treatment wet scrubbers are widely used in the purification treatment of acid and alkaline waste gas discharged from the production process of chemicals, electronics, metallurgy, electroplating, textile (chemical fiber), food, machinery manufacturing, and other industries.